Engineers and equipment designers often face a challenge where lifting assistance is not enough; the load must also stop and hold securely at specific positions. A locking gas strut solves this by integrating a specialized valve mechanism into the piston. Unlike standard compression springs that always exert outward force, a lockable gas strut allows the user to stop the stroke at any point. This capability makes it essential for applications requiring height adjustment or complex posture control, such as medical beds and adjustable desks.

The Internal Mechanism: Nitrogen and The Valve

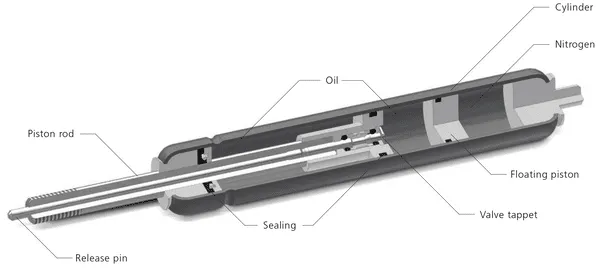

A gas spring consists of multiple seals, a rod, a piston, and a cylinder filled with nitrogen and a small amount of oil for lubrication. In a standard spring, the gas moves freely from one side of the piston to the other through a small orifice, creating constant pressure. However, the locking gas strut introduces a plunger valve inside the piston.

This valve remains closed by default. When closed, the gas or oil cannot flow between the chambers, effectively locking the piston in place. This mechanism creates a rigid or elastic lock depending on the medium utilized in the design. As a professional gas springs manufacturer operating since 2007, Gastac engineers these internal seals to withstand high pressure, ensuring the lock remains secure even under heavy loads.

Controlling the Movement: The Release Pin

The user operates the strut through a specific actuation method. The hollow rod contains a release pin that extends through the center of the shaft. By pushing in this pin, the operator forces the internal piston valve to open. This action opens the flow path for the nitrogen and oil, enabling the rod to compress or extend freely like a standard spring.

Once the operator stops pushing the pin, the valve closes instantly. The rod locks at that exact position of the usable stroke length. The lockable gas strut is versatile and found in many applications to help lifting, balancing, or lowering objects without using external air or hydraulic equipment. This self-contained design simplifies the assembly process for manufacturers.

Critical Application Scenarios

Safety and precision are the two primary reasons to select this component. For example, in industrial machinery, these springs protect material and equipment underneath heavy loads. They act as a safety device for heavy covers or access hatches.

-

Medical Equipment: Adjusting the angle of hospital beds or physiotherapy tables requires the strut to lock firmly to support the patient’s weight.

-

Machine Guards: They lock automatically when fully extended, ensuring they cannot be closed until the operator actively releases them. This prevents accidental closures during maintenance.

-

Ergonomic Furniture: Used in height-adjustable tables where the user needs to frequently change positions.

Key Technical Parameters

When selecting a Gastac gas spring, engineers must consider specific metrics to match locking gas struts to the application. Below are the standard specifications we adhere to under our ISO 9001:2015 and IATF 16949 quality management systems.

10-22 Locking Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Suspa Cross Reference |

| GTK102220110 | 20 | 110 | 90 | 10/22 | 80-400N | 2752293 |

| GTK102230130 | 30 | 130 | 100 | 10/22 | 80-400N | 2752294 |

| GTK102240150 | 40 | 150 | 110 | 10/22 | 80-400N | 2752295 |

| GTK102260190 | 60 | 190 | 130 | 10/22 | 80-400N | 2752296 |

| GTK102280230 | 80 | 230 | 150 | 10/22 | 80-400N | 2752297 |

| GTK1022100270 | 100 | 270 | 170 | 10/22 | 80-400N | 2752298 |

| GTK1022120310 | 120 | 310 | 190 | 10/22 | 80-400N | 2752299 |

| GTK1022160390 | 160 | 390 | 230 | 10/22 | 80-400N | 2752300 |

| GTK1022200470 | 200 | 470 | 270 | 10/22 | 80-400N | 2752301 |

| GTK1022250570 | 250 | 570 | 340 | 10/22 | 80-400N | 2752302 |

10/26 Locking Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Suspa Cross Reference |

| GTK102620110 | 20 | 110 | 90 | 10/28 | 100-800N | 2752304 |

| GTK102630130 | 30 | 130 | 100 | 10/28 | 100-800N | 2752305 |

| GTK102640150 | 40 | 150 | 110 | 10/28 | 100-800N | 2752306 |

| GTK102660190 | 60 | 190 | 130 | 10/28 | 100-800N | 2752307 |

| GTK102680230 | 80 | 230 | 150 | 10/28 | 100-800N | 2752308 |

| GTK1026100270 | 100 | 270 | 170 | 10/28 | 100-800N | 2752309 |

| GTK1026120310 | 120 | 310 | 190 | 10/28 | 100-800N | 2752310 |

| GTK1026160390 | 160 | 390 | 230 | 10/28 | 100-800N | 2752311 |

| GTK1026200470 | 200 | 470 | 270 | 10/28 | 100-800N | 2752312 |

| GTK1026250570 | 250 | 570 | 340 | 10/28 | 100-800N | 2752313 |

By managing the entire production process in-house, we provide stable quality with a significant price advantage, ensuring you stay competitive in your market. Whether you need a single prototype or bulk procurement support, our engineering team verifies every parameter before shipment.

Installation Guide: Release Systems & Mounting

Proper installation is critical for the function of the release mechanism. Since the release pin is located at the end of the rod, you must pair the gas spring with a compatible release head or cable system.

XHJ001

XHJ002

XHJ003

XHJ004

XHJ005

XHJ006

-

Mounting Orientation: Gas springs have a ball socket end fitting and ball stud on each end for mounting. Ball socket end fittings rotate in any direction on the ball stud to compensate for misalignment. However, ensure the release head has enough clearance to move.

-

Actuation Setup: Pull on the knob or squeeze the lever to unlock. Ensure the cable or lever exerts force directly on the release pin in a straight line. Side-loading the pin can cause internal valve wear or failure.

-

Rod Protection: Never scratch or paint the piston rod. Imperfections on the rod surface will damage the seals, causing gas leakage and failure of the locking function.

Conclusion

Understanding the internal valve mechanism of a locking gas strut ensures you select the right component for safety and precision. As a dedicated gas springs supplier, Gastac supports every stage of your project. You can view detailed specifications on our Product Page, purchase individual units directly through our Retail Shop, or reach out to our engineering team for customizable bulk orders.

Contact Us for a Quote today and secure your equipment with our two-year after-sales warranty.

Ian Martin

Stay in the loop