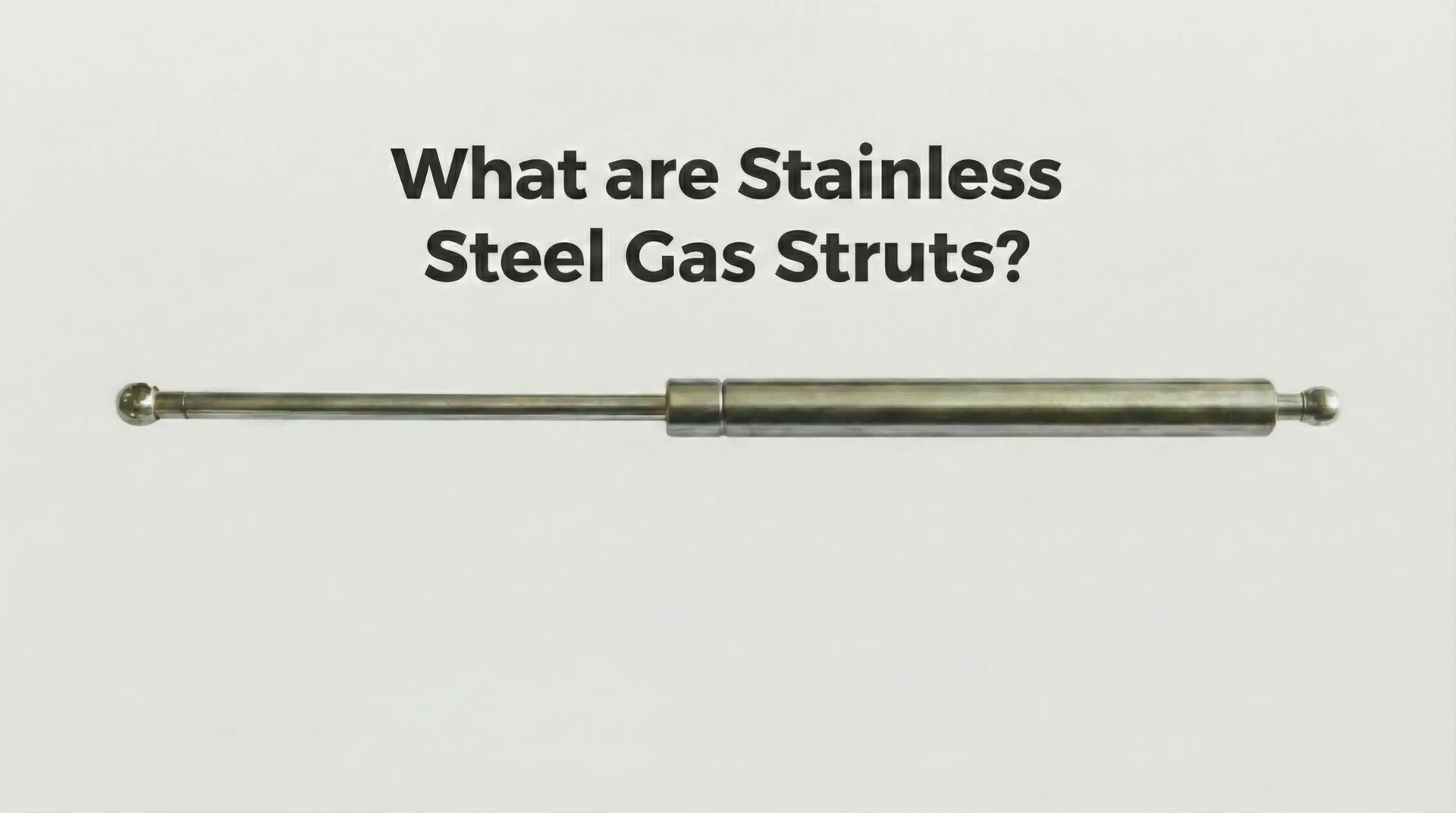

Stainless steel gas struts are gas-filled support components made from 316L stainless steel. They help lift, lower, and stabilize lids or panels, especially in environments where corrosion resistance and cleanliness are essential. As a gas springs manufacturer and gas springs supplier since 2007, Gastac offers OEM-friendly and wholesale-supported solutions certified under IATF 16949 and ISO 9001:2015. We ensure stable quality with cost advantage, helping engineers and procurement managers achieve long-lasting reliability without overspending.

Material & Functional Advantages

316L stainless steel delivers excellent corrosion resistance and smooth performance in humid, marine, or food-grade environments. Each strut surface is precision-hardened, reducing micro-scratches and ensuring a smooth piston motion — engineers often describe it as a “clean, silent slide.” Inside, nitrogen and oil separation keeps damping stable even after thousands of cycles, maintaining control and safety across long-term use.

Application Scenarios

If your equipment operates near seawater, steam, or chemicals, stainless gas struts outperform carbon-steel alternatives. They’re widely used in marine hatches, medical equipment, industrial machinery, and food service enclosures, where corrosion resistance and cleanliness are crucial. Unlike standard struts, Gastac gas springs maintain consistent output force and long service life under repeated cycles.

To explore detailed specifications, view our stainless steel gas struts catalog or contact Gastac for technical support.

We Offer 4 Sizes of Stainless Steel Gas Springs

We offer a wide variety of gas spring types and sizes, including Mini-Size (4mm x 12mm), CompactSize (6mm x 15mm), Standard-Size (8mm x 18mm) and Heavy Duty-Size (10mm x 22mm) gas springs. Our mini-size gas springs are ideal for applications that require small size and low force.

Our in-stock sizes include:

| Style | Stroke Range | P1 Pressure Range |

|---|---|---|

| Mini-Size (4mm x 12mm) | .9” to 3.4” | 5 to 20 lbs. |

| Compact-Size (6mm x 15mm) | 2” to 8” | 10 to 100 lbs. |

| Standard-Size (8mm x 18mm) | 3 ½” to 8” | 20 to 150 lbs. |

| Heavy-Duty-Size (10mm x 22mm) | 15” | 120 to 250 lbs. |

Custom Solutions & Supply Reliability

For projects requiring specific force or stroke, Gastac gas strut production can be customized precisely to your design needs. Our flexible supply chain allows us to manufacture to order and hold stock for scheduled delivery worldwide. This model supports OEM customers who value consistency and reliability, ensuring your production line never pauses due to missing components.

Common Mistakes When Choosing Stainless Gas Struts

Using carbon-steel struts in corrosive environments is a common mistake — they rust quickly and lose sealing efficiency. Another is installing struts in the wrong orientation. Always mount rod-down to keep internal lubrication stable. Consulting Gastac engineers during design helps avoid rework and ensures long product life.

Connector Options

Gastac provides a full selection of end fittings and mounting connectors, such as ball joints, eyelets, clevis brackets, and threaded ends. Each connector is engineered for secure, easy installation to suit different application geometries.

Gas strut Ball Ends

Gas strut Ball Ends

Gas strut ball ends, also called ball joints or ball sockets, are essential fittings that connect gas springs securely to mounting points. They allow smooth pivoting movement, reduce wear, and improve load transfer. Available in steel, stainless, or plastic, ball ends ensure durability, easy installation, and reliable performance in varied applications.

Eye End Fittings

Eye End Fittings

Eye end fittings are precision-engineered connectors that attach gas springs to brackets or mounting points, providing a secure and stable connection. They allow controlled pivoting motion, reduce wear, extend the lifespan of the gas strut, and enhance operational safety. Eye end fittings are suitable for automotive, marine, industrial, and furniture applications.

Female Rod Ends

Female Rod Ends

Female rod ends provide a precise connection point between the gas strut and mounting hardware. Designed for controlled pivoting, they ensure smooth movement, reliable load transfer, and stable alignment. These connectors make installation straightforward while maintaining consistent performance and safety.

Conclusion

Stainless steel gas struts combine durability, hygiene, and corrosion resistance for demanding industries. With Gastac’s two decades of expertise as a gas springs manufacturer, OEM customization, and cost advantage, you gain confidence in every lift and motion. For bulk or custom solutions, contact Gastac today or view our stainless steel gas springs page.

If you need small-batch or single-piece purchases, you can also visit our Gastac Retail Shop for direct online ordering.

Ian Martin

Stay in the loop