- 1. Introduction: The Ultimate Choice for Demanding Applications

- 2. Understanding 316 Stainless Steel: The Material Science Behind Superior Performance

- 3. Key Performance Advantages of Stainless Gas Springs

- 4. Application-Specific Advantages Across Industries

- 5. Available Stainless Steel Configurations: Matching Solutions to Applications

- 6. Technical Specifications: Understanding the Numbers

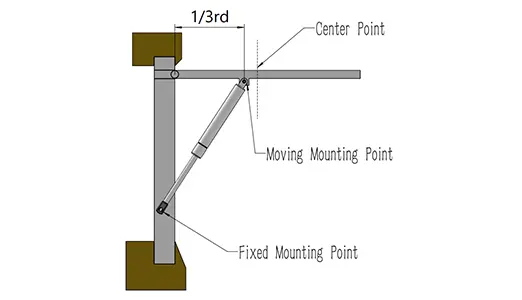

- 7. Installation Best Practices for Maximum Performance

- Conclusion: The Value of Investing in Quality

- Final Summary: Why Choose 316 Stainless Steel Gas Struts?

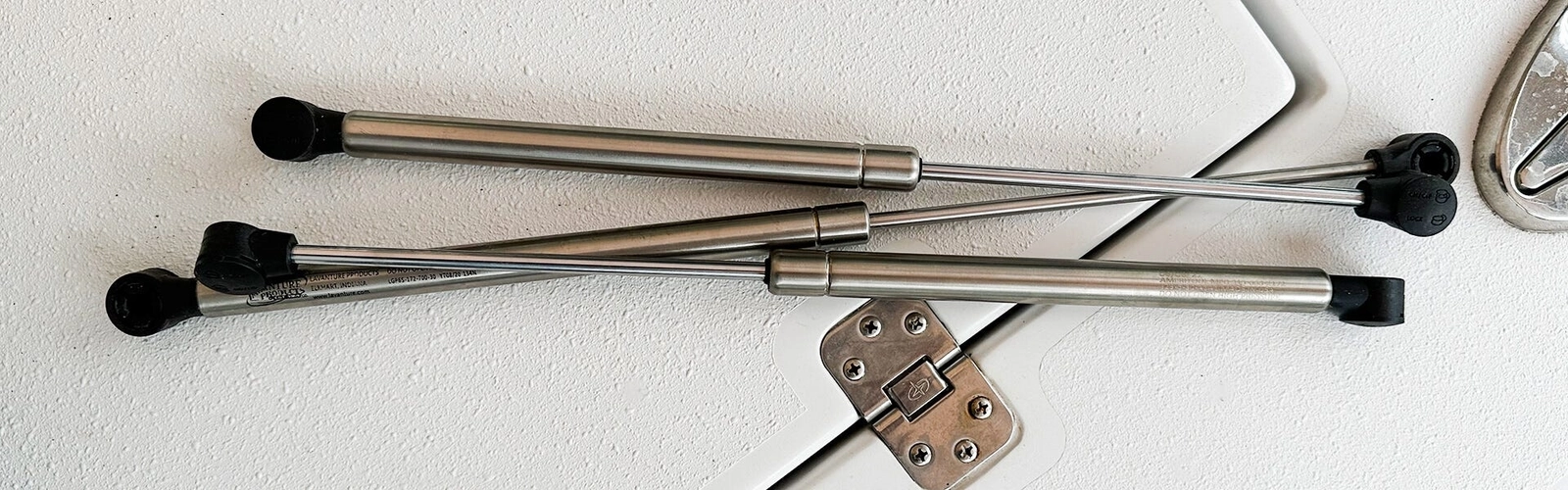

Marine Stainless Steel Gas Struts

1. Introduction: The Ultimate Choice for Demanding Applications

When operating equipment in corrosive, high-moisture, or contamination-sensitive environments, standard gas springs simply won’t suffice. 316 stainless steel gas struts represent the gold standard for applications where durability, hygiene, and longevity are non-negotiable. Throughout my 25 years as a Senior Design Engineer at Gastac, a leading global gas spring manufacturer, I’ve witnessed countless failures of inferior materials in marine, food processing, and pharmaceutical settings—failures that could have been prevented with the right specification from the start.

These specialized pneumatic devices, constructed primarily from 316 or 316L grade stainless steel, deliver exceptional corrosion resistance while maintaining precise force control. Unlike their carbon steel counterparts, stainless steel gas springs (often referred to as stainless gas shocks in heavy-duty applications) thrive in environments that would rapidly degrade conventional solutions, making them the preferred choice for industries where equipment failure is costly.

2. Understanding 316 Stainless Steel: The Material Science Behind Superior Performance

2.1 Why 316 Grade Makes the Difference

The designation “316” refers to a specific austenitic stainless steel alloy containing chromium (16-18%), nickel (10-14%), and crucially, molybdenum (2-3%). This molybdenum content is what sets 316 stainless steel apart from the more common 304 grade, providing substantially enhanced resistance to chloride corrosion and pitting in saltwater and acidic environments.

In practical terms, I’ve specified 316 stainless steel gas struts for offshore platforms where 304 grade units failed within months. The molybdenum creates a more stable passive oxide layer on the metal surface, which self-repairs when scratched and prevents the electrochemical reactions that lead to rust and structural degradation.

The 316L variant (the “L” denotes low carbon content, typically below 0.03%) offers even greater corrosion resistance and improved weldability, making it ideal for applications requiring sanitary welding or exposure to aggressive chemicals. According to industry testing standards, 316L stainless steel demonstrates exceptional performance in salt spray tests exceeding 144 hours—a benchmark that speaks directly to its longevity in harsh marine and industrial environments.

2.2 Chrome-Plated Rods: An Additional Layer of Protection

While the 316 stainless steel body provides the primary corrosion barrier, many manufacturers enhance their stainless gas struts with chrome-plated piston rods. This additional treatment serves multiple purposes:

Surface hardness: Chrome plating increases surface hardness to 800-1000 HV, reducing wear from repeated cycling

Reduced friction: The smooth chrome surface minimizes friction coefficients, improving operational efficiency

Seal protection: Enhanced surface finish extends seal life by preventing premature wear

Corrosion redundancy: Provides a secondary barrier against environmental attack

From my experience working with food processing equipment, this dual-layer protection system is particularly valuable in washdown environments where high-pressure cleaning with caustic solutions occurs multiple times daily.

3. Key Performance Advantages of Stainless Gas Springs

3.1 Unmatched Corrosion Resistance in Extreme Environments

The primary advantage of 316 stainless steel gas struts is their ability to maintain structural integrity and operational performance in conditions that would rapidly compromise standard materials. I’ve documented performance data from installations across various industries:

- 1

Marine Applications: In saltwater exposure tests conducted on dock boxes and boat hatches, 316 stainless steel gas struts showed zero visible corrosion after 5 years. The chloride-rich environment accelerates corrosion in most metals, making these specialized marine gas springs the only reliable choice for long-term ocean exposure.

- 2

Chemical Processing: Pharmaceutical manufacturing facilities require equipment that can withstand regular sterilization. Standard gas struts deteriorate rapidly under such conditions. The through-hardened corrosion resistance of 316 stainless steel eliminates this failure mode entirely.

- 3

Food Industry Compliance: Many stainless steel gas springs incorporate USDA H1 food-grade oil, combining material compliance with lubricant safety. This dual certification ensures complete suitability for direct and incidental food contact applications.

3.2 Force Range Versatility and Precision Control

Modern 316 stainless steel gas struts are available in comprehensive force ranges to accommodate diverse application requirements:

| Rod Diameter | Force Range | Typical Applications |

|---|---|---|

| 6mm | 30-400N (7-90 lbs) | Light hatches, inspection panels, small enclosures |

| 8mm | 50-650N (11-146 lbs) | Medium access doors, equipment guards, marine hatches |

| 10mm | 70-1200N (16-270 lbs) | Heavy machinery covers, industrial access panels |

| 14mm | 200-2500N (45-562 lbs) | Large hatches, vehicle applications, heavy equipment |

What distinguishes quality stainless steel gas struts is their adjustability. Most models incorporate release valves that allow precise force tuning in the field—a feature I consider essential for applications where load conditions may vary. The exception is micro-sized units, which are typically sealed due to their compact dimensions.

3.3 Extended Service Life Through Superior Engineering

The combination of material excellence and design sophistication results in exceptional operational longevity. High-quality 316 stainless steel gas struts incorporate several features that extend service life:

Low Electrolytic Capacity: The 316 alloy’s composition minimizes galvanic corrosion potential when coupled with dissimilar metals.

Low Magnetic Signature: Minimal magnetic permeability (typically μr < 1.02) prevents operational conflicts in sensitive electronics.

Protective Design Elements: Protective tubes or collars shield the piston rod from impact damage and contamination.

High Cycle Design: Premium units are engineered for 50,000+ cycles under rated load conditions.

4. Application-Specific Advantages Across Industries

4.1 Marine and Offshore: Conquering Saltwater Challenges

The marine environment represents perhaps the most demanding application for gas struts. Constant saltwater spray, humidity, and UV exposure create a perfect storm for corrosion. I’ve specified marine gas springs for:

Dock boxes and hatches: Where conventional units fail within one season.

Boat engine compartments: Combining saltwater exposure with fuel vapors and heat.

Offshore platform access panels: Where replacement costs are multiplied by logistics.

Naval applications: Meeting stringent military specifications.

A case study from a marina installation demonstrated that while 316 stainless steel gas struts cost more initially, they eliminated annual replacement cycles, reducing total cost of ownership by 60% over 5 years.

4.2 Food Processing and Pharmaceutical: Meeting Hygiene Standards

In food and pharmaceutical manufacturing, equipment must satisfy dual requirements: corrosion resistance and hygienic design. Stainless steel gas springs excel in both areas:

Cleanability: The smooth, non-porous surface resists bacterial colonization and facilitates thorough cleaning.

Chemical Resistance: The 316 alloy resists chlorine-based sanitizers and acidic cleaners.

Temperature Tolerance: Maintains performance from freezer applications (-40°C) to hot washdown environments (+80°C).

Regulatory Compliance: Ensures compliance with FDA and USDA safety regulations.

4.3 Industrial and Petrochemical: Handling Aggressive Environments

Chemical processing and heavy industry present corrosive atmospheres that challenge standard gas struts. Applications I’ve specified include:

Chemical storage tank access

Refinery equipment covers

Wastewater treatment plants (H2S exposure)

Mining equipment dealing with dust and moisture

5. Available Stainless Steel Configurations: Matching Solutions to Applications

5.1 Compression Gas Struts: The Standard Workhorse

Compression-type stainless steel gas springs represent the most common configuration, providing pushing force to lift and support hatches. The gas-filled cylinder extends when load is reduced, providing controlled motion.

From my design experience, I always recommend consulting force-stroke-angle calculations rather than estimating—incorrect specification leads to premature wear.

5.2 Tension Gas Struts: Reverse-Acting Solutions

Tension or reverse-acting gas struts pull rather than push, ideal for applications requiring closing assistance. I’ve successfully applied tension stainless steel gas struts in belt tensioners and downward-opening hatches. These variants typically offer forces up to 85 lbs (380N).

5.3 Locking Gas Struts: Infinite Positioning Capability

Locking stainless steel gas struts allow the strut to be locked at any point in its stroke. This feature is invaluable for medical equipment and adjustable work surfaces. In stainless steel construction, these units maintain the same corrosion resistance as standard models while offering enhanced versatility.

5.4 Micro Gas Struts: Compact Solutions

For applications with limited space, micro stainless steel gas struts provide force assistance in remarkably compact packages (strokes from 1-3.5 inches). These find application in electronic enclosures and medical devices.

6. Technical Specifications: Understanding the Numbers

6.1 Standard Sizing and Force Ranges

Understanding the relationship between rod diameter, body dimensions, and force capacity is essential for specifying the correct stainless steel gas springs:

6mm Rod Systems: For light-duty applications (30-400N).

8mm Rod Systems: For medium-duty doors and marine hatches (50-650N).

10mm Rod Systems: For heavy machinery covers (70-1200N).

14mm Rod Systems: For very heavy industrial equipment (200-2500N).

6.2 Performance Testing and Certification

As a quality-focused gas spring manufacturer, we ensure our products undergo rigorous testing:

Salt Spray Testing: ASTM B117 testing for 144+ hours demonstrates corrosion resistance.

Cycle Testing: Validates fatigue life and seal integrity.

Temperature & Pressure Testing: Ensures consistent force characteristics across operating ranges.

7. Installation Best Practices for Maximum Performance

Proper installation is as important as correct specification. Key factors include:

Mounting Angle: Gas struts are most efficient when mounted to provide 80-90% of required force at the fully open position.

Stroke Clearance: Ensure sufficient clearance for full extension without interference.

Side Load Prevention: Use ball socket ends to minimize angular loads and prevent binding.

Drawing Check: Always check the technical drawing provided by your gas spring supplier before installation.

Conclusion: The Value of Investing in Quality

In critical applications where reliability, safety, and hygiene are paramount, the initial investment in 316 stainless steel gas struts pays dividends through extended service life. As a Design Engineer with 25 years of experience at Gastac, I can confidently state that for harsh environments, there is no substitute for proper materials.

Final Summary: Why Choose 316 Stainless Steel Gas Struts?

Unmatched Corrosion Resistance: Ideal for marine and chemical environments.

Hygienic Design: Meets strict sanitary standards for food/medical use.

Versatile Performance: Available in compression, tension, and locking configurations.

Professional Reliability: Backed by rigorous testing.

Need help selecting the right stainless gas spring for your project?

Contact Gastac, your trusted stainless steel gas spring supplier, today for a custom calculation and quote.

Ian Martin

Stay in the loop