- Understanding the Suspa Gas Spring Catalog Structure

- Key Technical Parameters in the Suspa Gas Spring Catalog

- GASTAC Compatibility With Suspa Series 16 Models

- Cross-Referencing GASTAC Models to the Suspa Gas Spring Catalog

- Technical Specifications Comparison: GASTAC vs. Suspa

- Application-Specific Selection Using the Suspa Gas Spring Catalog

- Quality Assurance and Certification

- Cost Advantages of GASTAC AlternativesGASTAC

- Procurement, Availability, and Lead Times

- Installation and Replacement Best Practices

- Technical Support and Cross-Reference Assistance

- Why GASTAC Is a Smart Alternative to the Suspa Gas Spring Catalog

GASTAC Gas Springs Compatible With Suspa Gas Spring Catalog

When searching for reliable gas spring replacements, a clear understanding of the Suspa gas spring catalog is essential. It allows engineers and procurement specialists to identify accurate specifications and select compatible alternatives. GASTAC, as a professional gas spring manufacturer, produces gas springs that directly cross-reference with Suspa Series 16 models, offering cost-effective solutions without compromising dimensional accuracy or performance standards.

Understanding the Suspa Gas Spring Catalog Structure

The Suspa gas spring catalog is widely recognized as an industry reference for pneumatic lifting and damping solutions. SUSPA publishes comprehensive technical documentation, including its general product catalog “Gas Springs, Dampers and Adjustment Systems”, which details the complete Series 16 product family—covering types 16-1, 16-2, 16-3, 16-4, and 16-6.

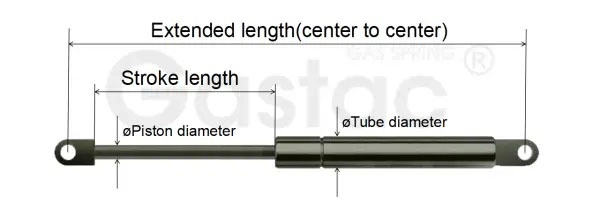

Each product listed in the catalog follows a structured part-number system that defines critical technical parameters. For example, a code such as 16-3-262-200-A285-B144-400N specifies the series type (16-3), tube length (262 mm), stroke (200 mm), end-thread configurations (A285 and B144), and the extension force (400 N). This standardized format makes accurate cross-referencing possible.

Key Technical Parameters in the Suspa Gas Spring Catalog

The Suspa gas spring catalog organizes products according to several essential specifications:

- Tube Diameter Classifications: Series 16 gas springs range from compact 16-1 models to heavy-duty 16-6 variants, designed for different load requirements and installation spaces.

- Rod Diameter Specifications: Rod diameter directly affects load capacity, rigidity, and cycle durability, all clearly defined for each series.

- Stroke Length Ranges: The catalog provides detailed tables showing valid combinations of tube length and stroke for each model.

- Force Ranges: Extension forces typically range from 100 N to over 2000 N, depending on series and configuration.

GASTAC Compatibility With Suspa Series 16 Models

GASTAC has engineered its gas spring product line to maintain full dimensional and functional compatibility with the Suspa gas spring catalog, enabling seamless replacement across a wide range of applications.

Dimensional Interchange Standards

GASTAC gas springs match Suspa specifications for tube diameter, rod diameter, extended length, and compressed length. This ensures installation without modification to mounting points or surrounding structures.

Thread configurations also align precisely with Suspa’s A and B designations, including common M6, M8, and M10 threads with standard pitch options.

Performance Characteristic Matching

Beyond dimensions, GASTAC carefully matches performance behavior. Force curves, damping response, and internal pressure ratings are engineered to mirror those documented in the Suspa gas spring catalog.

Extension forces are calibrated within industry-standard tolerances to ensure that replacing a Suspa unit with a GASTAC equivalent does not alter mechanical balance or user experience.

Cross-Referencing GASTAC Models to the Suspa Gas Spring Catalog

Accurate replacement begins with systematic cross-referencing using the Suspa gas spring catalog.

- Identify the Suspa Part Number: Locate the full code on the existing gas spring.

- Decode the Specifications: Break the part number into series, tube length, stroke, end fittings, and force rating.

- Match the GASTAC Equivalent: Use GASTAC compatibility charts or distributor databases.

- Verify Critical Parameters: Confirm mounting interfaces, force rating, and overall length before installation.

Technical Specifications Comparison: GASTAC vs. Suspa

Materials and Construction

Both GASTAC and Suspa use high-grade steel tubing with precision-honed interiors. Piston rods are hardened and chrome-plated for corrosion resistance, while sealing systems employ multi-lip designs to ensure long-term pressure retention.

GASTAC maintains equivalent material grades to those specified in the Suspa gas spring catalog, particularly for automotive and outdoor applications.

Cycle Life and Operating Conditions

The Suspa gas spring catalog defines expected cycle life under standard conditions. GASTAC designs its compatible gas springs to meet or exceed these benchmarks, typically 50,000–100,000 cycles.

Operating temperature ranges (commonly -30 °C to +80 °C) are fully matched.

Application-Specific Selection Using the Suspa Gas Spring Catalog

- Automotive Applications: Series 16-2 and 16-3 gas springs are commonly used for hoods, trunks, and tailgates. GASTAC provides direct automotive-grade replacements.

- Industrial Equipment: Series 16-4 and 16-6 models support higher loads in machinery covers, safety guards, and access panels. GASTAC equivalents meet the same structural demands.

- Furniture and Cabinetry: Series 16-1 gas springs serve lighter-duty applications where compact size and controlled force are critical. GASTAC offers economical alternatives with precise force control.

Quality Assurance and Certification

GASTAC manufactures gas springs under ISO 9001 quality management systems. Each unit undergoes force testing, seal integrity validation, cycle-life testing, and temperature performance checks to ensure compliance with catalog specifications.

Cost Advantages of GASTAC AlternativesGASTAC

While the Suspa gas spring catalog defines OEM standards, GASTAC-compatible gas springs typically deliver 20–40% cost savings. This advantage becomes especially meaningful for high-volume production and maintenance programs, without increasing total cost of ownership.

Procurement, Availability, and Lead Times

GASTAC maintains inventory for common Series 16 configurations. Standard models often ship within 1–3 business days, while custom specifications require 2–4 weeks.

Many distributors stock both Suspa and GASTAC products, allowing flexible sourcing and fast replacement.

Installation and Replacement Best Practices

Gas springs store pressurized energy and should be handled carefully. Follow standard safety procedures and ensure loads are properly supported during replacement.

Install GASTAC gas springs following the same orientation guidelines specified in the Suspa gas spring catalog—typically with the piston rod facing downward to optimize lubrication and seal life.

Technical Support and Cross-Reference Assistance

GASTAC provides experienced technical support teams capable of interpreting Suspa catalog data and recommending accurate equivalents. Distributors with cross-reference databases can often deliver same-day quotations and technical confirmation.

Why GASTAC Is a Smart Alternative to the Suspa Gas Spring Catalog

The Suspa gas spring catalog remains the definitive reference for gas spring specifications across automotive, industrial, and commercial applications. GASTAC has strategically aligned its product range with these standards, delivering compatible gas springs that match Suspa specifications in dimension, performance, and reliability.

By leveraging Suspa catalog data and GASTAC cross-reference solutions, engineers and procurement professionals gain flexibility, cost efficiency, and supply-chain resilience—without compromising performance.

张航

Stay in the loop