- Introduction

- What Are Tension Gas Springs?

- How Tension Gas Springs Work: The Operating Principle

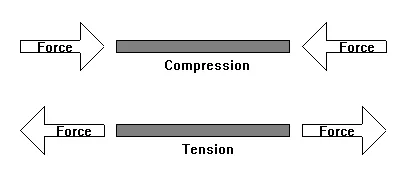

- Tension vs. Compression Gas Springs: Critical Differences

- When to Choose Tension Over Compression

- Types of Tension Gas Springs

- Force Calculation for Tension Gas Springs

- Selection Criteria for Tension Gas Springs

- Common Applications

- Installation Best Practices

- Maintenance and Safety Guidelines

- Troubleshooting Common Issues

- Conclusion: Customizing for Success

Tension Gas Struts

Introduction

As a design engineer with 25 years of experience at a leading gas spring manufacturer, I’ve witnessed firsthand how tension gas springs have revolutionized motion control across countless industries. These pneumatic devices generate pulling forces through compressed nitrogen gas and oil sealed within a cylinder—operating in the exact opposite manner of their compression counterparts. Unlike traditional metal tension springs with coils, a modern tension gas strut delivers quieter operation, adjustable force characteristics, and superior performance in space-constrained applications where conventional compression mechanisms simply won’t work.

Throughout my career, I’ve helped engineers select and customize pull type gas struts for applications ranging from aerospace throttle controls to medical equipment, and I’ve learned that understanding their working principles and proper force calculation is essential for successful implementation. In this comprehensive guide, I’ll share the technical knowledge and practical insights I’ve accumulated over two and a half decades, helping you make informed decisions.

What Are Tension Gas Springs?

Tension gas springs (often referred to in the industry as a traction gas spring, pull gas strut, or pulling gas spring) are pneumatic devices that create retracting forces by utilizing compressed nitrogen gas and hydraulic oil within a sealed cylinder assembly. They remain in an extended position at rest and generate a retracting force when activated, fundamentally operating opposite to standard compression gas springs that push outward.

Core Components and Construction

From my extensive work with these mechanisms, I can tell you that every traction gas strut comprises several critical components working in harmony:

- 1

Sealed Cylinder Body: The outer tube contains pressurized nitrogen gas (typically between 1,000-2,000 PSI) and a small amount of hydraulic oil. The cylinder must maintain absolute seal integrity.

- 2

Piston Rod Assembly: A precision-ground chrome-plated steel rod passes through the cylinder seal. As a specialized gas spring supplier, we ensure the rod’s surface finish is critical to prevent premature seal wear.

- 3

Piston with Sealing System: Inside the cylinder, the piston divides the gas chamber while allowing controlled oil flow.

- 4

End Fittings: Mounting hardware on both the cylinder and rod ends enables secure attachment.

How Tension Gas Springs Work: The Operating Principle

Understanding the working principle of a tension gas strut has been fundamental to my success in designing custom solutions. Let me break down the mechanical process step by step.

The Default Extended State

In its resting position, the piston rod of a pulling gas spring remains fully extended. At this point, gas pressure exists on both sides of the piston, creating an equilibrium state.

Energy Storage Through Compression

When you apply an external force to push the piston rod inward (or pull the cylinder housing away from the rod), you’re compressing the nitrogen gas inside the chamber. This compression increases gas pressure proportionally to the stroke distance. The relationship follows the ideal gas law (PV = nRT), though in practice, we account for real gas behavior and temperature effects.

The Retraction Force Generation

Here’s where the magic happens: when you remove the external force, the compressed gas expands, pushing the piston and pulling the rod back to its extended position. This creates the characteristic pulling force that defines a traction gas spring. The force magnitude depends on gas pressure, piston area, and stroke position.

Damping Mechanisms (When Present)

In applications requiring controlled motion, I often specify pull type gas struts with integrated damping. This is achieved through precisely sized orifices in the piston that restrict oil flow during compression or extension.

Tension vs. Compression Gas Springs: Critical Differences

After thousands of application consultations, I’ve found that many engineers initially confuse a tension gas spring with a compression one. Let me clarify the fundamental distinctions:

| Characteristic | Tension Gas Strut | Compression Gas Strut |

|---|---|---|

| Resting State | Rod fully extended | Rod fully compressed |

| Force Direction | Pulling/retracting force | Pushing/extending force |

| Default Action | Pulls components together | Pushes components apart |

| Energy Storage | Compressed when rod pushed in | Compressed when rod pushed in |

| Typical Mounting | Both ends under tension | One end fixed, one end pushing |

When to Choose Tension Over Compression

In my experience, a pull gas strut excels in specific scenarios:

- 1

Space-Constrained Designs: When your application lacks room for a compression spring’s extended length.

- 2

Pulling Force Requirements: Applications requiring components to be drawn together rather than pushed apart.

- 3

Inverted Mounting Situations: Cases where mounting geometry makes compression springs impractical but tension gas struts can be easily integrated.

Types of Tension Gas Springs

Throughout my career, I’ve worked with three primary configurations, each serving distinct application requirements:

Non-Damped Tension Gas Springs

These represent the simplest configuration—pure weight balancing without motion control. I typically recommend these basic pull type gas struts for static counterbalancing applications or cost-sensitive projects where motion control isn’t critical.

Damped Tension Gas Springs

Adding controlled damping transforms the spring into a motion control device. In my designs, I’ve utilized damped traction gas struts for:

- Medical Equipment: Controlled lowering of examination tables.

- Automotive Interiors: Glove box lids that need soft-close functionality.

These sophisticated variants incorporate a locking mechanism that holds the rod at any position along its stroke. As a gas spring manufacturer, we often customize these for adjustable height mechanisms in furniture or medical devices.

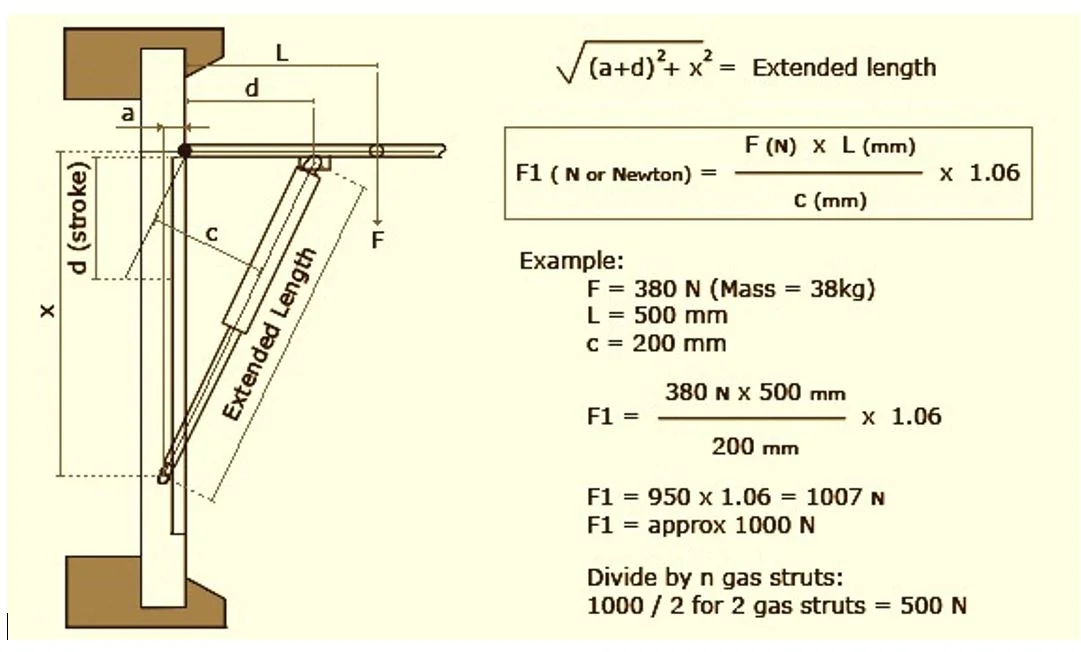

Force Calculation for Tension Gas Springs

Accurate force calculation has been the cornerstone of every successful project.

Understanding Force Requirements

Before calculating specifications for your pulling gas spring, determine:

-

F1 (Extended Force): The pulling force when fully extended.

-

F2 (Compressed Force): The pulling force when fully compressed.

-

Working Force: The actual force required at your mounting geometry.

The Fundamental Force Formula

The basic force equation is: F = P × A However, in real applications, I must account for the K-factor.

Force Progression and K-Factor

The K-factor (progression ratio) describes how force increases during compression (K = F2 / F1). For a high-quality tension gas spring, typical K-factors range from 1.05 to 1.8.

Practical Calculation Example:

Let’s say you need to counterbalance a 50 kg load. You determine the tension gas strut must provide 400N at full extension.

-

Required K-factor: 1.2

-

Selection: Cylinder diameter 22mm, Rod diameter 10mm.

Selection Criteria for Tension Gas Springs

Selecting the optimal traction gas spring involves balancing multiple parameters:

-

Load Analysis: Define Static, Dynamic, and Peak loads.

-

Stroke and Mounting Space: Calculate the linear distance the spring must move.

-

Cycle Life: For high-cycle applications, verify the testing data from your gas spring supplier.

-

Environmental Considerations: For corrosive environments, request stainless steel pull gas struts.

-

End Fitting Selection: Use Ball Sockets if there is any misalignment.

Common Applications

My experience spans diverse industries where pull type gas struts are essential:

-

Automotive: Throttle control systems and convertible top mechanisms.

-

Medical: Examination tables and patient lifts.

-

Industrial: Cable tensioning systems and heavy machine guard counterbalancing.

-

Furniture: Adjustable office chairs and garage doors.

Installation Best Practices

Proper installation is critical for achieving design performance and service life.

-

Pre-Installation Verification: Inspect for shipping damage.

-

Measure Mounting Points: Re-verify the distance between mounting centers.

-

Rod Orientation Matters: Unlike compression struts, a tension gas spring often has specific orientation requirements. Always check the drawing provided by your gas spring manufacturer.

-

Avoid Side Loading: This is the #1 killer of gas springs.

-

Pro Tip: Use ball-socket end fittings to allow articulation.

-

-

Protect the Rod: Never paint or clamp onto the piston rod.

Maintenance and Safety Guidelines

-

Never Open or Puncture: Tension gas struts contain nitrogen at high pressure.

-

Visual Inspections: Check for oil leaks on the rod.

-

No Lubrication Needed: The internal oil supply lasts the life of the unit.

Troubleshooting Common Issues

-

Loss of Force: Gas has likely leaked. Contact your gas spring supplier for a replacement.

-

Rough Operation: Check for a bent rod or side-loading.

-

Won’t Retract Fully: Check for debris blocking the mounting points.

Conclusion: Customizing for Success

Tension gas springs are deceptively simple devices that solve complex engineering challenges. But success lies in the details: calculating the correct force and ensuring perfect alignment.

With 25 years of design experience, I know that “off-the-shelf” isn’t always the answer. Whether you need a standard replacement or a custom-engineered traction gas spring solution, choosing the right partner is key.

Ready to optimize your design? Don’t leave your application’s performance to chance. Contact us—your trusted gas spring manufacturer—today to help you run the calculations and find the perfect solution.

Ian Martin

Stay in the loop