Stainless steel gas struts (also known as gas springs or lift supports) are durable, corrosion-resistant components designed for applications in harsh environments such as marine, medical, food processing, and chemical industries. They are available in various sizes, force ranges, and material grades to suit specific needs.

But when is the upgrade strictly necessary? The answer depends on your environment. If your project involves saltwater, harsh chemicals, or requires strict hygiene standards, stainless gas struts are the only way to prevent rust and mechanical failure.

Real-World Scenarios: When Standard Steel Fails

To help you decide, here are three typical situations where switching to stainless steel is not just an upgrade, but a necessity:

- The “Salt Spray” Test (Marine Use): If you are outfitting a boat hatch or engine cover, standard painted steel will inevitably fail. Salt particles in the air accelerate oxidation, causing the piston rod to pit and the seal to leak. Stainless gas struts withstand this aggressive salinity, ensuring your hatch opens smoothly every time, season after season.

- The Hygiene Requirement (Food & Medical): In food processing plants or medical facilities, equipment undergoes frequent washdowns with harsh detergents. Paint chips from standard carbon steel struts can contaminate production lines. Our 316L stainless option eliminates the risk of peeling paint and maintains a sterile, easy-to-clean surface.

- The Outdoor Aesthetic (Weather Resistance): For high-end outdoor furniture, roof boxes, or signage, appearance matters. A rusty strut bleeding orange stains onto your product looks unprofessional. Stainless steel maintains its polished look despite rain, humidity, and UV exposure.

The Core Advantage: Why 316L?

Standard steel rusts, but 316L Stainless steel gas springs and struts are good for a wide variety of corrosive environments. This specific material choice will help reduce any corrosion that may occur on the spring, ensuring longevity even when exposed to the elements.

As a dedicated gas springs manufacturer (certified IATF 16949 & ISO 9001:2015), GASTAC guarantees that every gastac gas spring is built to last. All stainless steel struts and springs are made of 316L stainless steel.

Stainless Steel Gas Spring Features:

- 1All stock 316L stainless steel gas springs use USDA H1 food grade oil

- 2Designed & built to the highest gas spring manufacturing standards

- 3High life cycle design

- 4Low electrolytic capacity & Low magnetic signature

- 5Ideal for marine, petrochemical, pharmaceutical, medical, and food industry applications

We support versatile needs. All micro, compression, locking, and tension gas springs are available in 316L stainless steel. Whether for urgent replacement or new production, we also stock the most popular 316L stainless steel compression gas spring sizes, and all others are manufactured to order.

Common Applications

Because they are clean and robust, these struts are used where standard steel cannot survive:

- Marine: Boat hatches, engine covers, and storage compartments.

- Industrial: Machinery, enclosures, and access panels.

- Medical: Equipment where sterilization and non-magnetic properties are required.

- Food Service: Food processing equipment and packaging machinery.

- Automotive: Liftgates, hoods, and truck beds.

- Outdoor Furniture: For weather resistance and longevity.

Technical Specifications: What sizes do you offer?

We offer a flexible range to match your machinery. We also offer a wide range of bespoke sizes depending on your requirements.

- Force Range: 50 – 2,500N

- Stroke Range: 20 – 1,000mm

- Rod diameter: 6, 8, 10 and 14mm

- Tube diameter: 15, 18, 23 and 28mm

- Thread Form: M5 to M10

6-15 Stainless Steel Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Lift Easy Cross Reference |

| GTS61515550 | 40 | 155 | 115 | 6/15 | 50-400 | GSSK15-155/050N |

| GTS61519550 | 60 | 225 | 165 | 6/15 | 50-400 | GSSK15-195/050N |

| GTS61523550 | 80 | 235 | 155 | 6/15 | 50-400 | GSSK15-235/050N |

| GTS61525550 | 80 | 255 | 175 | 6/15 | 50-400 | GSSK15-255/050N |

| GTS61527550 | 100 | 275 | 175 | 6/15 | 50-400 | GSSK15-275/050N |

| GTS61531550 | 120 | 315 | 195 | 6/15 | 50-400 | GSSK15-315/050N |

| GTS61533050 | 125 | 330 | 205 | 6/15 | 50-400 | GSSK15-330/050N |

| GTS61537550 | 150 | 375 | 225 | 6/15 | 50-400 | GSSK15-375/050N |

| GTS61539050 | 160 | 390 | 230 | 6/15 | 50-400 | GSSK15-390/050N |

| GTS61543050 | 175 | 430 | 255 | 6/15 | 50-400 | GSSK15-430/050N |

| GTS61550550 | 210 | 505 | 295 | 6/15 | 50-400 | GSSK15-505/050N |

For detailed technical parameters and full specifications, please visit our product page.

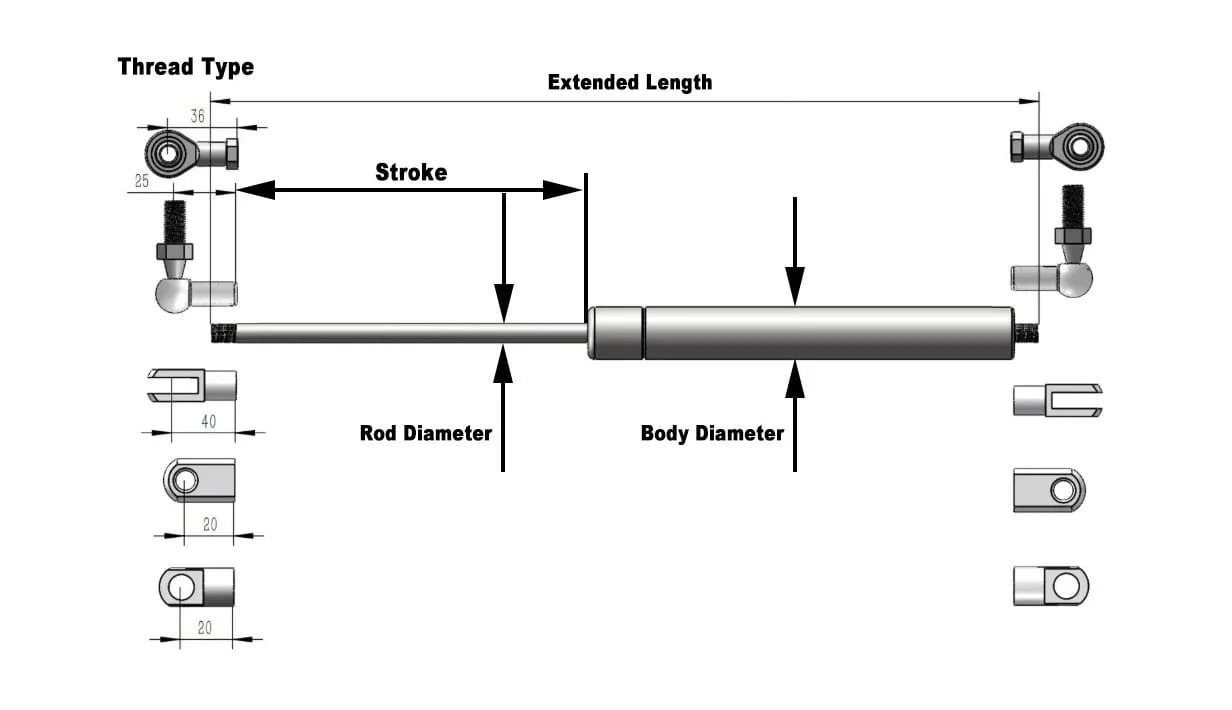

How to Measure for the Correct Fit

Installing the wrong size is a common issue. When selecting or replacing a gas spring, it is important to measure the key dimensions accurately.

- 1Rod & Tube: Start with the Rod Diameter and Body Diameter, which determine the strength and load capacity of the gas spring.

- 2Stroke: Next, measure the Stroke, which is the distance the rod can travel between the fully compressed and fully extended positions.

- 3Extended Length: Finally, record the Extended Length, which is the total length of the gas spring from the center of one end fitting to the other when fully extended.

By following these steps, you can ensure the correct specifications for your application and achieve reliable performance.

Ready for Reliable Performance?

Don’t let rust compromise your equipment’s safety or function. Whether you are upgrading a marine hatch or designing medical machinery, choosing a gastac gas strut ensures long-term durability.

- You can view our Stainless Steel Gas Springs page to see detailed specifications, technical parameters, and load charts for our 316L line.

- If you need a replacement fast, please visit our online shop to browse our most popular sizes available for immediate retail shipping.

- For specific stroke lengths, force settings, or wholesale pricing, please contact us for a quote.

As a trusted gas springs supplier since 2007, we offer precise customization and a two-year after-sales warranty.

Ian Martin

Stay in the loop