Engineers face demanding challenges when motion control matters. Many projects involve limited space, reverse force directions, and strict durability goals. Therefore, traction gas springs deliver strong value. These compact devices generate force during extension, not compression. They help designers create smoother movements with clean control. They also simplify system layouts in tight environments. Consequently, more industries are adopting traction gas springs for machines, vehicles, and equipment.

What are Traction Gas Springs?

Traction gas springs, also called pull-type or tension gas struts, are self-contained pneumatic devices that generate force during extension rather than compression. They exert a controlled pulling force that draws components inward. Inside the cylinder, nitrogen gas and a sealed rod create constant tension for covers, hatches, lids, and mechanisms that must stay closed or be pulled back safely and consistently.

Key Benefits of Traction Gas Springs

Traction gas springs offer consistent performance throughout the stroke, controlling energy without friction noise while improving user feel and safety. They appear in bicycle racks, cabinets, ramps, folding desks, yacht building, and industrial machinery. Their sealed gas design extends service life and reduces hardware. New installation models, co-developed with Gastac gas spring, provide longer lifespan and flexible mounting.

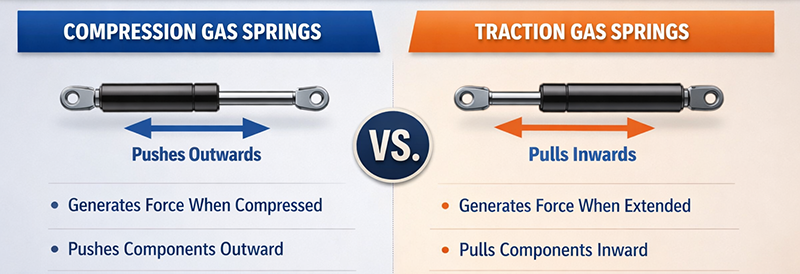

What is the Difference Between Compression and Traction Gas Springs?

Compression gas springs push outward. However, traction gas struts pull inward. This simple difference changes the entire force profile. As a result, engineers get controlled tension in small envelopes. Many medical devices, sports equipment, and industrial tools rely on traction gas struts for stable tension. The motion feels smooth. The force remains consistent. The design becomes cleaner, and the final product feels more refined.

Ordinarily compression gas struts are just called “gas springs”. It is only when we look at traction gas struts that we add a word indicating a particular property.

GASTAC Traction Gas Springs

GASTAC manufactures industrial traction gas springs with strict quality controls. Engineers trust GASTAC for consistent force curves, corrosion protection, and long service life. Moreover, GASTAC offers custom tuning to fit unique force and length requirements. As a result, OEM builders, aftermarket brands, and industrial users benefit from better reliability and lower cost. GASTAC supports small orders and large production runs. This gives buyers flexibility during prototyping and scaling.

Traction Gas Struts Size Chart

GASTAC provides standard traction gas struts through its online store. Designers can quickly select force values, stroke lengths, and end fittings. Therefore, purchasing becomes faster and simpler. The catalog supports many industries, including automotive, marine, fitness, industrial machinery, and specialty equipment. The online store includes data sheets for efficient decision-making. This reduces engineering time and ensures excellent performance matching.Below are standard traction gas struts specifications available through the GASTAC store:

| ID | Rod Ø | Body Ø | Stroke | Extended Length | Force(Lbs) |

|---|---|---|---|---|---|

| GST102245720 | 0.39 in | 0.87 in | 6 in | 18.00 in | 25-300 |

| GST102243713 | 0.39 in | 0.87 in | 6 in | 17.21 in | 25-300 |

| GST102241626 | 0.39 in | 0.87 in | 6 in | 18.16 in | 25-300 |

| GST102253340 | 0.39 in | 0.87 in | 8 in | 21.00 in | 25-300 |

| GST102251333 | 0.39 in | 0.87 in | 8 in | 20.21 in | 25-300 |

| GST102253746 | 0.39 in | 0.87 in | 8 in | 20.21 in | 25-300 |

| GST102233426 | 0.39 in | 0.87 in | 3.50 in | 13.16 in | 25-300 |

| GST102231013 | 0.39 in | 0.87 in | 3.50 in | 12.21 in | 25-300 |

| GST102233020 | 0.39 in | 0.87 in | 3.50 in | 13.00 in | 25-300 |

| GST102228346 | 0.39 in | 0.87 in | 3 in | 11.16 in | 25-300 |

| GST102225933 | 0.39 in | 0.87 in | 3 in | 10.21 in | 25-300 |

| GST102227940 | 0.39 in | 0.87 in | 3 in | 11.00 in | 25-300 |

| GST102221996 | 0.39 in | 0.87 in | 2.25 in | 8.66 in | 25-300 |

| GST102219583 | 0.39 in | 0.87 in | 2.25 in | 7.71 in | 25-300 |

| GST102221590 | 0.39 in | 0.87 in | 2.25 in | 8.50 in | 25-300 |

Selecting the Right Traction Gas Springs

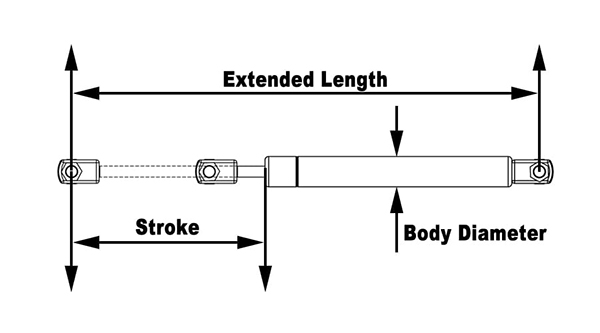

Choosing the right traction gas springs requires simple steps. First, identify stroke length and extended length. Next, determine required traction force. Then confirm available installation space. Afterward, check your mounting hardware and end fittings. Consider cylinder materials, damping options, and longevity requirements. Finally, evaluate operating environment factors such as temperature, corrosion, and vibration. These steps help reduce redesign time and ensure reliable performance.

Selecting the Right Traction Gas Springs

Choosing the right traction gas springs requires simple steps. First, identify stroke length and extended length. Next, determine required traction force. Then confirm available installation space. Afterward, check your mounting hardware and end fittings. Consider cylinder materials, damping options, and longevity requirements. Finally, evaluate operating environment factors such as temperature, corrosion, and vibration. These steps help reduce redesign time and ensure reliable performance.

张航

Stay in the loop