You should choose a mini gas spring when your application requires controlled, predictable motion in a confined space where standard gas struts cause excessive force, unstable movement, or installation interference. The right choice depends on whether space constraints limit component size, whether motion behavior matters more than raw force, and whether incorrect sizing could impact usability or safety. By understanding application context, common mistakes, and correct measurement, engineers can confidently select the right mini gas struts from the start.

What a Mini Gas Spring Actually Solves in Compact Designs

A mini gas spring is designed to restore motion control where space constraints make standard gas struts impractical. In compact assemblies, oversized components often result in abrupt opening, difficulty closing, or interference with adjacent parts. By reducing physical size while maintaining functional balance, mini gas struts enable smooth lifting, holding, or damping without forcing a full redesign of the mechanism.

As a long-established gas springs manufacturer and gas springs supplier, Gastac focuses on translating technical parameters into real-world performance. With production systems certified to IATF 16949 and ISO 9001:2015, consistency in motion and durability becomes a practical benefit rather than a theoretical claim.

Product Definition and Material Options

Introducing our mini gas struts, designed to achieve an effective balance between compact size and usable force. In applications where space constraints limit component selection, these springs allow engineers to maintain efficiency and reliability without oversizing the structure.

Often referred to as mini gas struts, micro gas springs, or small gas springs, these compact components are used across electronics, medical, and automotive applications. In projects that require repeatable motion performance and consistent supply, engineers often standardize on solutions such as the gastac gas spring or gastac gas strut, selecting them as branded components rather than interchangeable hardware.

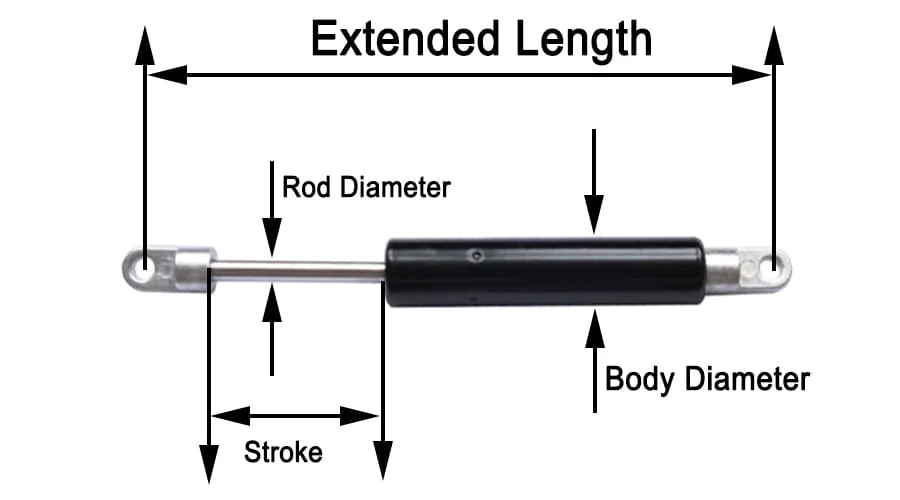

| Item | Rod Diameter | Body Diameter | Stroke | Extended Length | Thread Type | Force Range (lbs) |

| MGT412-1 | 4 mm (0.16 in) | 12 mm (0.47 in) | 29.97 mm (1.18 in) | 98.91 mm (3.89 in.) | M4x0.7 | 2.5-35 |

| MGT412-2 | 4 mm (0.16 in) | 12 mm (0.47 in) | 39.88 mm (1.57 in) | 118.97 mm (4.68 in.) | M4x0.7 | 2.5-35 |

| MGT412-3 | 4 mm (0.16 in) | 12 mm (0.47 in) | 55.12 mm (2.17 in) | 147.93 mm (5.82 in.) | M4x0.7 | 2.5-35 |

| MGT412-4 | 4 mm (0.16 in) | 12 mm (0.47 in) | 65.02 mm (2.56 in) | 168 mm (6.61 in.) | M4x0.7 | 2.5-35 |

| MGT412-5 | 4 mm (0.16 in) | 12 mm (0.47 in) | 80.01 mm (3.15 in) | 198.98 mm (7.83 in.) | M4x0.7 | 2.5-35 |

| MGT412-6 | 4 mm (0.16 in) | 12 mm (0.47 in) | 89.92 mm (3.54 in) | 219.04 mm (8.62 in.) | M4x0.7 | 2.5-35 |

| MGT412-7 | 4 mm (0.16 in) | 12 mm (0.47 in) | 29.97 mm (1.18 in) | 110.74 mm (4.36 in.) | M4x0.7 | 2.5-35 |

| MGT412-8 | 4 mm (0.16 in) | 12 mm (0.47 in) | 29.97 mm (1.18 in) | 114.81 mm (4.52 in.) | M4x0.7 | 2.5-35 |

| MGT412-9 | 4 mm (0.16 in) | 12 mm (0.47 in) | 39.88 mm (1.57 in) | 130.81 mm (5.15 in.) | M4x0.7 | 2.5-35 |

| MGT412-10 | 4 mm (0.16 in) | 12 mm (0.47 in) | 39.88 mm (1.57 in) | 134.87 mm (5.31 in.) | M4x0.7 | 2.5-35 |

| MGT412-11 | 4 mm (0.16 in) | 12 mm (0.47 in) | 55.12 mm (2.17 in) | 159.77 mm (6.29 in.) | M4x0.7 | 2.5-35 |

| MGT412-12 | 4 mm (0.16 in) | 12 mm (0.47 in) | 55.12 mm (2.17 in) | 163.83 mm (6.45 in.) | M4x0.7 | 2.5-35 |

| MGT412-13 | 4 mm (0.16 in) | 12 mm (0.47 in) | 65.02 mm (2.56 in) | 179.83 mm (7.08 in.) | M4x0.7 | 2.5-35 |

| MGT412-14 | 4 mm (0.16 in) | 12 mm (0.47 in) | 65.02 mm (2.56 in) | 183.9 mm (7.24 in.) | M4x0.7 | 2.5-35 |

| MGT412-15 | 4 mm (0.16 in) | 12 mm (0.47 in) | 80.01 mm (3.15 in) | 210.82 mm (8.3 in.) | M4x0.7 | 2.5-35 |

| MGT412-16 | 4 mm (0.16 in) | 12 mm (0.47 in) | 80.01 mm (3.15 in) | 214.88 mm (8.46 in.) | M4x0.7 | 2.5-35 |

| MGT412-17 | 4 mm (0.16 in) | 12 mm (0.47 in) | 89.92 mm (3.54 in) | 230.89 mm (9.09 in.) | M4x0.7 | 2.5-35 |

| MGT412-18 | 4 mm (0.16 in) | 12 mm (0.47 in) | 89.92 mm (3.54 in) | 234.95 mm (9.25 in.) | M4x0.7 | 2.5-35 |

Typical Applications Where Mini Size Changes the Result

If your application involves narrow housings, shallow panels, or limited hinge travel, a mini gas spring often delivers better results than a full-size strut. In electronic enclosures, it prevents sudden lid drop while eliminating the sharp metallic impact sound caused by oversized gas struts.

In medical equipment, smoother resistance improves operator comfort during frequent daily operation. In automotive interior components, predictable motion helps maintain perceived quality and reduces long-term wear on hinges and mounting points.

Common Mistakes to Avoid When Choosing a Mini Gas Spring

- 1

Choosing a mini gas struts simply because “smaller seems safer,” without verifying whether the force is sufficient to hold the panel open.

- 2Ignoring installation alignment, which can introduce side loading and lead to premature wear or faint squeaking sounds during operation.

- 3Overlooking early changes in resistance that often signal incorrect sizing or mounting geometry.

How to Measure and Size a Mini Gas Spring Correctly

Correct sizing begins with measuring real movement rather than relying on nominal dimensions. First, determine the actual stroke required between fully closed and fully open positions, ensuring the hinge reaches its true end position during measurement.

Next, translate panel weight and leverage into functional behavior. Instead of focusing solely on force values, engineers should evaluate whether the panel remains open smoothly and closes without excessive effort. This behavior-based approach leads to more reliable outcomes in compact designs.

Since 2007, Gastac has supported engineers with sizing guidance and customizable / OEM friendly solutions, helping projects move from prototype to mass production with fewer redesign cycles.

Usage Precautions for Long-Term Reliability

- Maintain correct mounting geometry and avoid forcing the gas spring beyond its intended motion range.

- Inspect mounting points periodically to detect looseness before it affects performance.

- Match material selection to the operating environment, especially in corrosive or hygiene-sensitive applications.

- We provide a clearly defined two-year after-sales warranty to support long-term reliability in real-world applications.

Making the Right Choice from the Start

Choosing the right mini gas spring—or mini gas struts—is about matching motion behavior to space limitations, not simply reducing size. With correct measurement, informed selection, and a reliable gas springs supplier, engineers can achieve stable motion, improved safety, and long-term performance in compact designs.

Backed by Bulk / Wholesale procurement support and stable quality with cost advantage, Gastac helps teams standardize reliable mini gas spring solutions across projects. If your application requires a customizable, OEM-friendly solution, contact Gastac to discuss your mini gas struts requirements.

Ian Martin

Stay in the loop