Choosing the right miniature gas spring starts with accurate sizing — every millimeter matters. An undersized unit can cause jerky or incomplete motion, while an oversized one may stress hinges or frames. By understanding how to calculate stroke, tube length, and total extension, you can design compact systems that move smoothly and last longer.

At Gastac, an IATF 16949 and ISO 9001:2015 certified gas springs manufacturer since 2007, we’ve helped engineers optimize miniature gas strut geometry for over a decade.

This article breaks down the exact calculation method and engineering logic you need to get your next precision design right from the first try.

Understanding Miniature Gas Struts Beyond the Specs

A miniature gas spring isn’t just a smaller version of a standard model—it’s a precision-engineered component designed for constrained spaces. It uses compressed nitrogen within a sealed cylinder to provide consistent, controlled motion for light to medium loads.

Instead of memorizing specs, think of it as an engineering lever that converts gas pressure into predictable motion control. Its compact form allows integration into:

- Instrument covers and inspection panels

- Compact medical devices

- Automotive glove boxes or center consoles

- Aerospace and electronics housings

Each Gastac gas strut is engineered for space efficiency and stable quality, ensuring repeatable damping and smooth motion under tight dimensional limits.

Why Engineers Misjudge Miniature Gas Spring Dimensions

Many designers underestimate how stroke length directly affects total extended length and mounting geometry.

A 20 mm stroke may require more than 50 mm of extended length due to mounting and end fittings.

Ignoring the rule A ≥ S + 30 can lead to interference or insufficient motion range.

Calculation & Measurement Guide: Getting It Right the First Time

1. Define Functional Requirements

Start with component weight (e.g., 10 kg lid):

Required Force ≈ Weight × 10 = 100 N

Then check:

-

Opening angle

-

Center of gravity distance

-

Mounting direction (rod down preferred)

Typical miniature struts range 50–400 N depending on torque load.

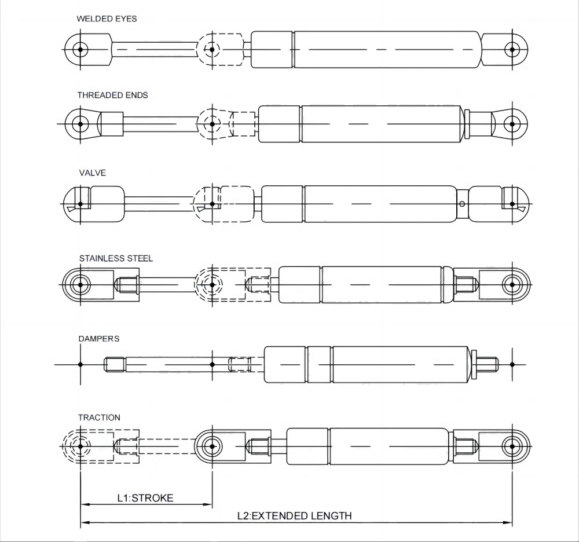

2. Determine Stroke and Total Length

Formula:

L = A (Tube length) + S (Stroke) + 13 + 13

A ≥ S + 30

Example: S = 20 mm → A ≥ 50 mm → L ≈ 96 mm

3. Verify Dimensional Compatibility

Confirm:

-

Extended length fits open position

-

Compressed length (L – S) fits closed space

-

Mounts aligned, no side load

4. Confirm Environmental & Material Choices

Use stainless steel miniature gas struts for corrosive or outdoor settings. Gastac’s IATF 16949 & ISO 9001:2015 certified manufacturing ensures automotive-grade sealing and corrosion resistance.

Application Scenarios: When Precision Size Matters

If your design leaves only millimeters of clearance, a Gastac gas spring offers the same control as larger units, miniaturized for tight spaces.

Examples:

-

In lab analyzers, it prevents lid drops.

-

In marine instruments, stainless versions resist humidity.

With OEM customization and bulk procurement support, Gastac ensures precise fit and consistent quality.

Usage Precautions for Longevity

- 1

Install rod down to lubricate seal.

- 2

Avoid side loads.

- 3

Keep within –30 °C to +80 °C.

- 4

Never open or refill.

- 5

Check oil film periodically.

Precision in Measurement Ensures Motion Control Success

Miniature gas springs may look simple, but precise sizing defines motion quality.

Correctly calculating stroke, tube length, and total extension avoids redesigns and ensures smooth, safe operation.

As a gas springs manufacturer since 2007, Gastac provides customizable, bulk-ready, IATF 16949-certified miniature solutions worldwide.

👉 Contact Gastac for tailored OEM gas strut calculations.

FAQs About Miniature Gas Springs

Rod down is recommended for seal lubrication.

Multiply weight (kg) × 10 to get Newtons; use 1.2 safety factor.

Gastac miniature gas struts are IATF 16949 and ISO 9001:2015 certified.

Yes, as a gas springs supplier, Gastac offers wholesale procurement support with stable quality and cost advantage.

Ian Martin

Stay in the loop