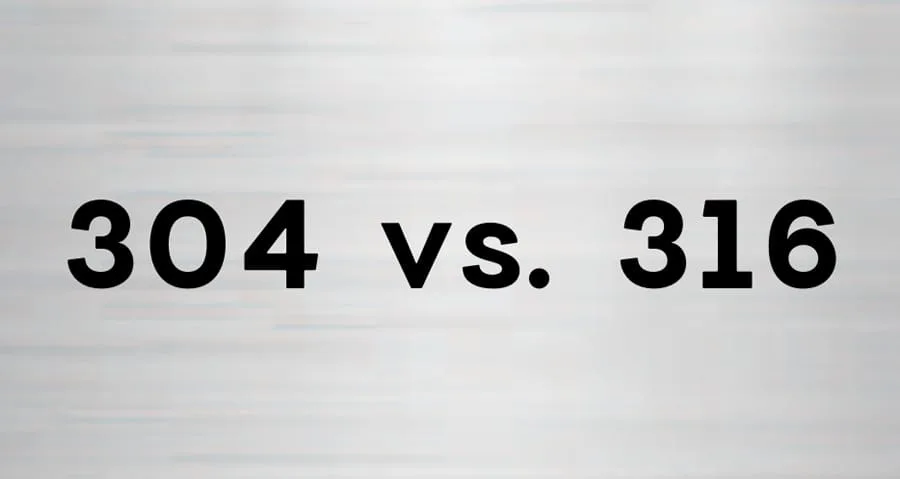

The big difference between stainless steel 304 and stainless steel 316L is in the composition of the materials, specifically the addition of molybdenum in 316L.

If you are asking this question, you are likely trying to decide which stainless gas spring fits your project. Here is the short answer: Stainless steel 316L contains 2% molybdenum, which makes it the superior choice for aggressive environments like marine or off-shore applications where resistance to chlorides (salt) is critical. In contrast, stainless steel 304 is an excellent solution for home-garden-and-kitchen applications but lacks the advanced protection needed for harsh industrial use.

The Material Science: Why 316L is Safer

Many users mistakenly believe all stainless gas shocks are the same. They are not.

Stainless steel 316L contains 2% molybdenum, which makes the material more resistant to crevice, pitting and stress corrosion cracking. The molybdenum in stainless steel 316L makes it less sensitive to chlorides. This property in combination with a higher percentage of nickel increases the corrosion resistance of stainless steel 316L.

On the other hand, the weak point of stainless steel 304 is its sensitivity to chlorides and acids, which can cause corrosion (local or otherwise).

Quick Comparison: 304 vs. 316L

| Feature | 304 Stainless Steel | 316L Stainless Steel (Gastac Standard) |

|---|---|---|

| Molybdenum Content | None | ~2.0% (Key for rust prevention) |

| Salt Water Resistance | Low (Risk of Pitting) | High (Marine Grade) |

| Chemical Resistance | Moderate | Excellent (Chlorides/Acids) |

| Ideal Application | Kitchen, Indoor Furniture | Boats, Food Plants, Medical |

So, if your application involves constant exposure to salt water or chemicals, choosing a gastac gas spring made of 316L is the only way to ensure stability.

Engineered for Aggressive Environments

A gas spring made of stainless steel is the solution for aggressive environments where chlorides and acids are used. Due to a different composition, this material is more resistant to corrosion and environmental influences, such as at the coast or in salt water.

But as a professional gas springs manufacturer (Since 2007), we know that material is only half the battle. In addition, gas springs made of stainless steel 316L are of higher quality. Our gastac gas strut designs include two critical features that simplify installation and maintenance:

- 1The Grease Chamber (Mount Anywhere): A grease chamber ensures that the seal of the gas springs is always well lubricated, so that it does not matter how the gas springs are positioned. These stainless steel gas springs can therefore also be mounted with the piston rod upwards or be positioned completely horizontally, without the seal drying out and the gas springs starting to leak.

- 2The Built-in Clean Cap (Self-Cleaning): A clean cap ensures that the piston rod is scraped clean, so that no dirt gets into the interior of the gas springs. As a result, the stainless steel 316L gas springs can also be used in dirty environments. It’s very multifunctional!

What is a Stainless Steel Gas Spring Used For?

Stainless steel gas springs function the same as their common hydraulic counterparts, but give an alternative when operating under rough conditions such as off-shore and other outdoor exposure applications.

Other common application areas for stainless gas spring include:

- Health care products (Sanitary requirements)

- Food industry (Washdown capability)

- Medical devices (Non-magnetic properties)

Customization Options & Why Choose Us

Every project is unique. As a reliable gas springs supplier certified with IATF 16949 and ISO 9001:2015, we offer a range of customization options to meet your specific needs. You don’t need to calculate complex parameters; we do it for you.

We offer a range of customization options to meet your specific needs:

- 1Force Calibration: Precise force settings tailored to your application.

- 2Mounting Accessories: Various end fittings and brackets to suit different mounting

- 3Surface Treatments: Additional coatings for enhanced corrosion resistance in extreme environments.

- 4Temperature Resistance: Seals and lubricants suitable for extreme temperatures.

Why Choose Our Stainless Steel Gas Springs?

- High-Quality Materials: Use of 316L stainless steel ensures durability and longevity.

- Versatility: Suitable for a wide range of applications across various industries.

- Compliance: Options available to meet industry-specific regulations, including food-grade requirements.

- Customization: Ability to tailor products to meet unique application needs.

- Support: Expert technical support to assist with product selection and customization.

Secure Your Equipment’s Future

Rust is expensive; switching to the right material is not. Whether you are designing a new medical device or retrofitting a fleet of marine vessels, Gastac has the 316L solution you need.

For detailed technical drawings and load charts, please check our Product Page. If you already have your specifications and need a competitive proposal, Contact Us directly—our engineering team typically responds within 24 hours. Prefer to buy standard sizes immediately? You can Visit Our Shop for quick delivery.

Ian Martin

Stay in the loop