When you choose a gas strut for your boat, you expect strength, smooth performance, and durability. GASTAC stainless steel gas struts deliver all three, with engineering that stands up to the harshest environments. From salty sea air to food processing washdowns, our struts keep working when others fail.

Why Choose GASTAC?

GASTAC stainless steel gas struts are crafted from premium 316L steel, ensuring excellent corrosion resistance for marine, medical, and industrial use. Tested over 1,000 hours in salt spray, they offer long-lasting durability. Options include food-grade oil and non-magnetic materials. Choose fixed or adjustable force, with smooth, quiet operation, and customizable lengths, forces, and fittings for any project.

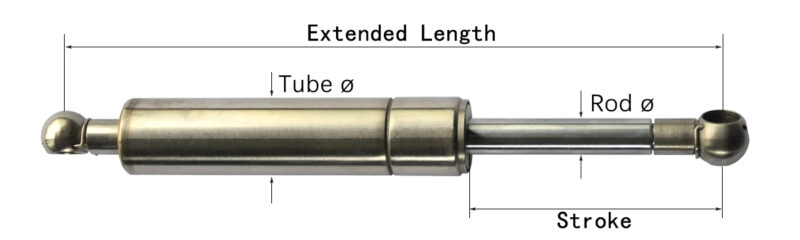

Expanded Stainless Steel Gas Struts Specifications

GASTAC stainless steel gas struts are precisely engineered for diverse applications. They offer a wide range of force ratings, strokes, and dimensions, all crafted from premium 316L stainless steel. Detailed specifications simplify selection, ensuring optimal performance, corrosion resistance, and durability for marine, food-safe, and medical uses. Adjustable and customizable options make them suitable for OEM, wholesale, and DIY projects.

| ID | Rod Dia (d) | Cylinder Dia (D) | Stroke (A) | Extended Length (L) | Compressed Length (CL) | End Detail | Force(Lbs) |

| 7502 Stainless Steel Gas Strut | 0.312 | 0.75 | 2.25 | 7.5 | 5.25 | 10mm | 10-150 Lbs. |

| 7503 Stainless Steel Gas Strut | 0.312 | 0.75 | 3 | 10 | 7 | 10mm | 10-150 Lbs. |

| 7504 Stainless Steel Gas Strut | 0.312 | 0.75 | 4 | 12 | 8 | 10mm | 10-150 Lbs. |

| 7506 Stainless Steel Gas Strut | 0.312 | 0.75 | 6 | 15 | 9 | 10mm | 10-150 Lbs. |

| 7506L Stainless Steel Gas Strut | 0.312 | 0.75 | 7 | 17 | 10 | 10mm | 10-150 Lbs. |

| 7507 Stainless Steel Gas Strut | 0.312 | 0.75 | 7.5 | 18.5 | 11.25 | 10mm | 10-150 Lbs. |

| 7508 Stainless Steel Gas Strut | 0.312 | 0.75 | 8 | 20 | 12 | 10mm | 10-150 Lbs. |

| 75010 Stainless Steel Gas Strut | 0.312 | 0.75 | 11 | 26 | 15 | 10mm | 10-150 Lbs. |

| 75010S Stainless Steel Gas Strut | 0.312 | 0.75 | 9.6 | 23 | 13.4 | 10mm | 10-150 Lbs. |

GASTAC’s Unmatched Brand Strength

GASTAC stands out from other gas spring brands with precise stroke control and customizable pressure options. Every strut ensures smooth, consistent movement across its full stroke length, while advanced pressure calibration delivers stable force in any setting. Built for durability, accuracy, and adaptability, GASTAC ensures reliable performance.

| Brand | Force (N) | Stroke (mm) |

| GASTAC | 50–3000 | 20–1200 |

| StrutDepot | 200–1200 | 100–600 |

| Suspa | 300–1500 | 150–800 |

| Stabilus | 500–2500 | 200–1000 |

| Ameritool | 200–1200 | 100–600 |

| Attwood | 300–1500 | 150–800 |

| Camloc | 50–400 | 25–560 |

| ASRaymond | 50–800 | 20–600 |

| SGS | 100–1500 | 50–1000 |

| Metrol Motion Control | 50–1200 | 25–600 |

| West Marine | 100–700 | 50–500 |

Force vs. Stroke Overview

Understanding force and stroke is key to choosing the right gas strut. GASTAC provides clear guidance matching gas struts to different lid weights and sizes. Lower forces suit small cabinets, medium forces handle RV windows and toolboxes, and higher forces support heavy boat hatches or industrial panels. This ensures smooth, safe, and reliable motion in all applications.

| Force (N) | Recommended Applications |

| 50–200 | Small cabinets, lightweight lids |

| 200–400 | Toolboxes, RV windows, medium cabinets |

| 400–700 | Boat hatches, dock boxes, medium-heavy lids |

| 700–1200 | Heavy doors, industrial panels |

| 1200–2500 | Large industrial doors, medical equipment |

How to Choose Right Gas Springs Size ?

To choose the right gas spring, consider extended length, stroke, rod and tube diameters, and end fittings. Ensure the force matches lid weight and application. Correct sizing guarantees smooth motion, safety, and durability. GASTAC offers customizable options for marine, food-safe, and medical environments.

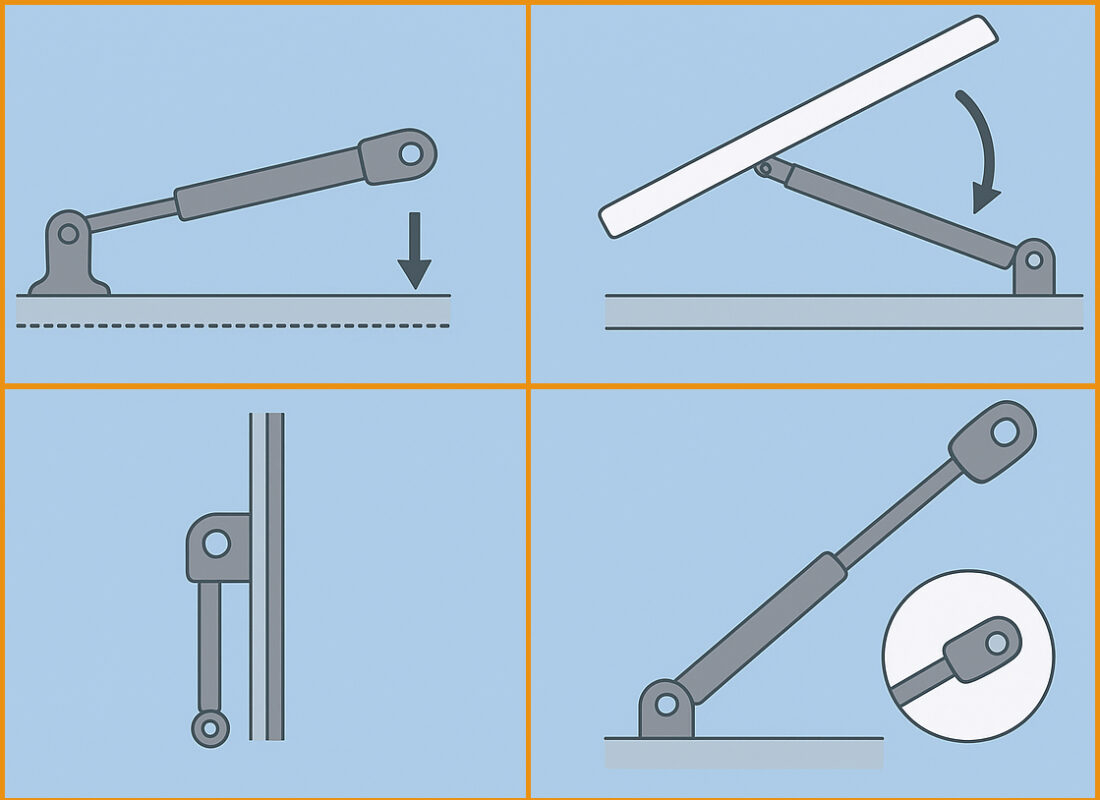

GASTAC Stainless Steel Gas Struts Installation Guide

Always mount gas springs with the rod pointing down to keep seals lubricated. Measure hinge positions and lid angles before drilling. Use strong stainless steel brackets and securely attach struts to ball sockets. Test the lid’s motion, and for adjustable models, fine-tune the force using the bleed valve for smooth, reliable operation.

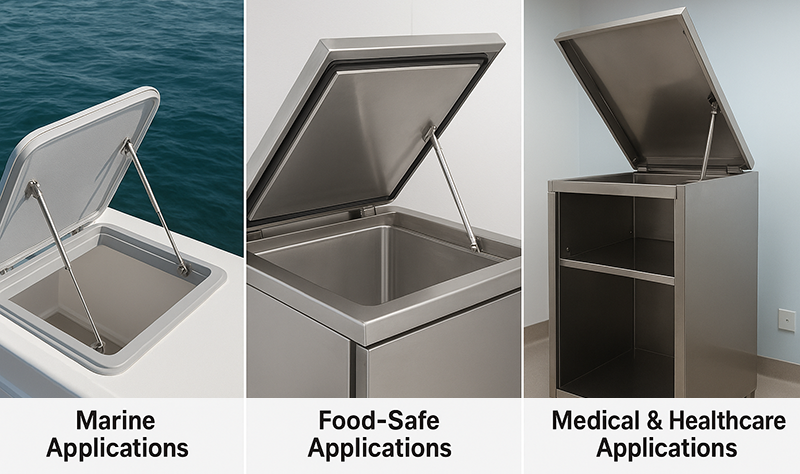

Applications of GASTAC Stainless Steel Gas Struts

Marine Applications: Engine covers, deck hatches, dock boxes, sailboat cabin lids.

Food-Safe Applications: Kitchen equipment lids, hygienic processing panels, beverage machinery, refrigerated display lids.

Medical & Healthcare Applications: MRI-safe cabinets, hospital bed lifts, instrument lids, laboratory storage compartments.

GASTAC Welcomes Gas Spring Partners

GASTAC welcomes global partners in the gas spring industry with open arms. With advanced manufacturing, certified quality, and flexible customization, we provide reliable support for distributors, OEMs, and project developers. Join us to expand markets, share innovation, and build long-term win-win cooperation.

Contact our team today for a custom quote or technical support, and discover how GASTAC can make your projects easier, safer, and more durable.

Frequently Asked Questions❓ (FAQ)

Having trouble with your gas springs? Don’t worry! Leave a comment below or email us directly. GASTAC’s expert team will provide a tailored solution just for you, ensuring smooth operation, safety, and long-lasting performance. Your perfect gas spring experience starts here!