Tension Gas Springs

Tension gas springs

Tension gas springs: In the ever-evolving world of fitness, where innovation and performance reign supreme, one often-overlooked component plays a pivotal role in delivering a superior workout experience: the tension gas strut. While its presence may be subtle, its impact is undeniable, transforming ordinary fitness equipment into precision-engineered machines that prioritize safety, comfort, and efficiency.

What is a tension gas spring?

A tension gas spring, also known as a tension spring or tension rod, is a type of gas spring that operates by compressing gas within a sealed cylinder to generate force. Unlike traditional gas springs that primarily work in compression (pushing), tension gas springs operate in tension (pulling).

In a tension gas spring, the rod is extended when the spring is in its neutral position. When the gas inside the cylinder is compressed, it creates tension, pulling the rod back into the cylinder. This tension force is utilized in various applications where a pulling or lifting force is needed.

How does a tension spring work?

Tension gas springs work in a different way unlike standard gas springs. They provide a controlled tension force instead of pressure force.

Tension gas springs are mostly used in situations where gas springs can’t be fitted or being preferred over gas springs.

When an opening is closed, the pull tension gas strut supports the manual force. It consists of a pressure tube and a piston rod with piston. In addition, a seal to prevent possible loss of gas is fitted at the piston rod guide. The tension gas strut is fitted with compressed gas – nitrogen which provides the spring force. In the unpressurised state, the piston rod is always retracted.

Pulling out the piston rod reduces the volume in the cylinder and the gas is compressed. This creates an increase in force (progression) for the spring, which depends on the diameter of the piston rod and the volume of the cylinder. The piston has a small opening (nozzle), through which the gas can flow. Thus, allowing the piston rod to move at a defined speed. The cross-section (diameter) of this opening defines the degree of damping of a spring.

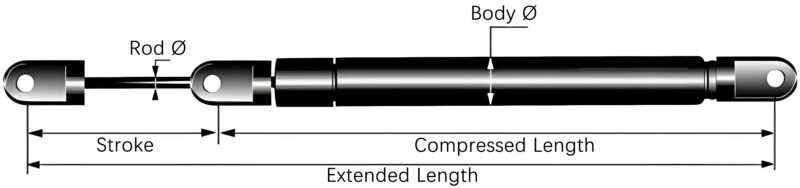

Tension Gas Springs Installation Dimensions

Some Specification Tension Gas Spring

| Product | Rod Ø | Body Ø | Force Range (lbs) | Stroke | Extended Length | Rod Thread Size | Body Thread Size |

| GST102221590 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 57.15 mm (2.25 in) | 215.90 mm (8.50 in) | M8x1.25 | M8x1.25 |

| GST102219583 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 57.15 mm (2.25 in) | 195.83 mm (7.71 in) | M8x1.25 | M8x1.25 |

| GST102221996 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 57.15 mm (2.25 in) | 219.96 mm (8.66 in) | M8x1.25 | M8x1.25 |

| GST102227940 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 76.20 mm (3 in) | 279.40 mm (11.00 in) | M8x1.25 | M8x1.25 |

| GST102225933 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 76.20 mm (3 in) | 259.33 mm (10.21 in) | M8x1.25 | M8x1.25 |

| GST102228346 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 76.20 mm (3 in) | 283.46 mm (11.16 in) | M8x1.25 | M8x1.25 |

| GST102233020 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 88.90 mm (3.50 in) | 330.20 mm (13.00 in) | M8x1.25 | M8x1.25 |

| GST102231013 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 88.90 mm (3.50 in) | 310.13 mm (12.21 in) | M8x1.25 | M8x1.25 |

| GST102233426 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 88.90 mm (3.50 in) | 334.26 mm (13.16 in) | M8x1.25 | M8x1.25 |

| GST102240640 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 139.70 mm (5.50 in) | 406.40 mm (16.00 in) | M8x1.25 | M8x1.25 |

| GST102238633 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 139.70 mm (5.50 in) | 386.33 mm (15.21 in) | M8x1.25 | M8x1.25 |

| GST102241046 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 139.70 mm (5.50 in) | 410.46 mm (16.16 in) | M8x1.25 | M8x1.25 |

| GST102245720 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 152.40 mm (6 in) | 457.20 mm (18.00 in) | M8x1.25 | M8x1.25 |

| GST102243713 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 152.40 mm (6 in) | 437.13 mm (17.21 in) | M8x1.25 | M8x1.25 |

| GST102241626 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 152.40 mm (6 in) | 461.26 mm (18.16 in) | M8x1.25 | M8x1.25 |

| GST102253340 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 203.20 mm (8 in) | 533.40 mm (21.00 in) | M8x1.25 | M8x1.25 |

| GST102251333 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 203.20 mm (8 in) | 513.33 mm (20.21 in) | M8x1.25 | M8x1.25 |

| GST102253746 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 203.20 mm (8 in) | 537.46 mm (21.16 in) | M8x1.25 | M8x1.25 |

| GST102262890 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 254.00 mm (10 in) | 628.90 mm (24.76 in) | M8x1.25 | M8x1.25 |

| GST102260884 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 254.00 mm (10 in) | 608.84 mm (23.97 in) | M8x1.25 | M8x1.25 |

| GST102263297 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 254.00 mm (10 in) | 632.97 mm (24.92 in) | M8x1.25 | M8x1.25 |

| GST102277114 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 317.50 mm (12.50 in) | 771.14 mm (30.36 in) | M8x1.25 | M8x1.25 |

| GST102275108 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 317.50 mm (12.50 in) | 751.08 mm (29.57 in) | M8x1.25 | M8x1.25 |

| GST102277521 | 10 mm (0.39 in) | 22.10 mm (0.87 in) | 25-300 | 317.50 mm (12.50 in) | 775.21 mm (30.52 in) | M8x1.25 | M8x1.25 |

What are the advantages of GASTAC tension gas springs?

GASTAC tension gas springs offer several advantages, including exceptional durability and reliability, ensuring long-lasting performance even under frequent use. They have a high load capacity and strength, supporting various applications with robust materials that resist corrosion and wear. These springs are easy to install and compatible with many setups, providing good value for money with affordable pricing. GASTAC offers customization options to meet specific needs, with quick availability and delivery times. They operate quietly, prioritize safety, and provide consistent performance, making them a dependable choice.

Tension Gas Springs Application

Common applications of tension gas springs include:

Lids and Hatches: Used in automotive, furniture, or industrial applications where a lid or hatch needs to be lifted or pulled open.

Counterbalance Systems: Employed to counterbalance the weight of certain objects, ensuring smooth and controlled movement.

Adjustable Systems: Integrated into designs where adjustable tension is required, such as in ergonomic furniture or equipment.

Doors and Gates: Used to assist in the controlled opening and closing of doors and gates.

Tension gas springs provide a controlled and reliable force, contributing to the safety and ease of operation in various mechanical and industrial applications.

Contact Us

Interested in our products, pricing, MOQ, or customized solutions? Fill out the form below to submit your inquiry or request a quote, and our team will get back to you within 24 hours.