- SUSPA Series 16 Overview & Applications for GASTAC Gas Springs

- Dimensional and Force Compatibility

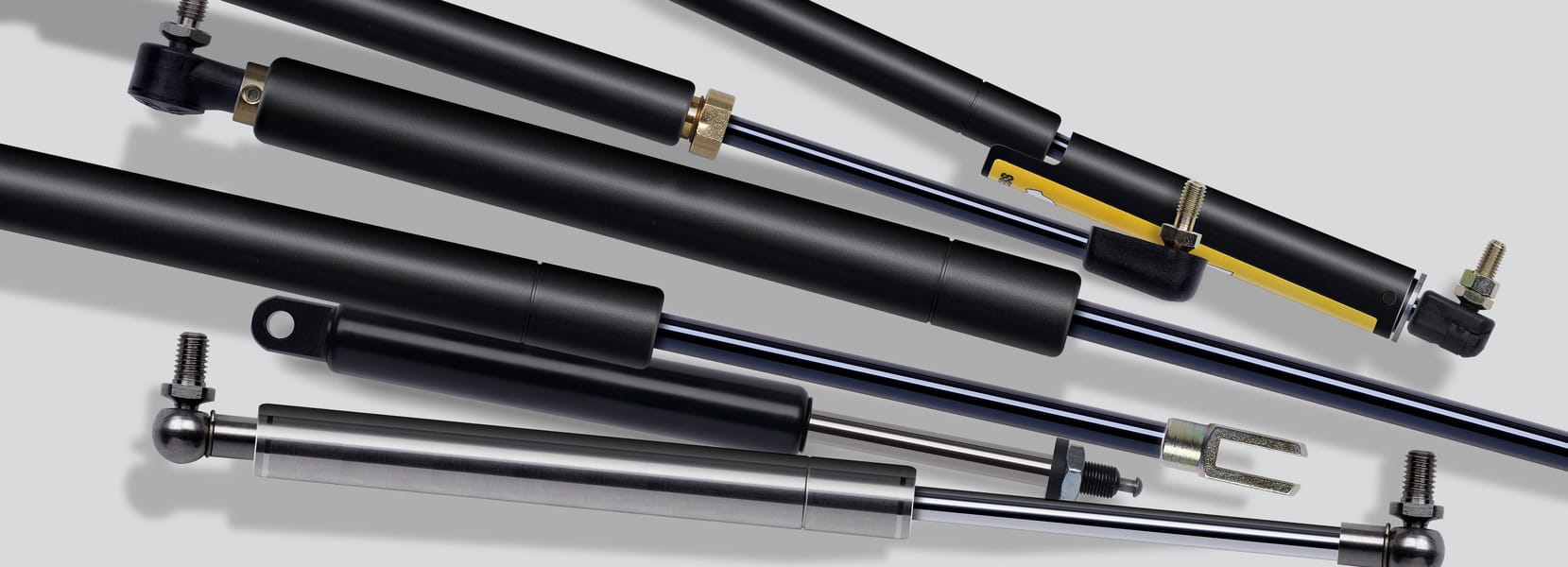

- End Fittings and Custom Configurations

- Performance, Damping & Reliability of GASTAC Gas Springs

- GASTAC Gas Springs Quality, Testing & Warranty Assurance

- GASTAC Gas Springs Applications Across Industries

- GASTAC to SUSPA Gas Springs Cross-Reference & Installation

- GASTAC Gas Springs Cost, Supply & Advantages

- Future Innovations in GASTAC Gas Springs & SUSPA Alternatives

GASTAC Gas Springs Compatible with Suspa Gas Spring Models

For over two decades, GASTAC has been providing high-quality gas springs for countless industrial, automotive, and furniture applications. Many engineers and maintenance professionals often ask whether GASTAC gas springs can replace SUSPA gas springs reliably. The answer is yes—but understanding the suspa gas spring catalog, including suspa part numbers, suspa replacement gas springs, and suspa replacement parts, is key for proper compatibility.

SUSPA Series 16 Overview & Applications for GASTAC Gas Springs

SUSPA’s Series 16 product family—including models 16-1, 16-2, 16-3, 16-4, and 16-6—is widely recognized for suspa lift, suspa hydraulic lift, and general lifting, counterbalancing, and damping applications. This series encompasses suspa cylinders, suspa gas props, suspa locking gas springs, and lighter-duty units like suspa 120N, making them suitable for industrial machinery, automotive components, and ergonomic furniture.

The suspa gas spring catalog provides standardized information on tube diameters, rod sizes, stroke lengths, and force ratings. Standardization ensures predictable performance and allows GASTAC gas springs to be directly cross-referenced to SUSPA models, enabling accurate replacement of suspa replacement gas springs and sourcing of suspa replacement parts.

Dimensional and Force Compatibility

When modifying or replacing SUSPA model gas struts, precise dimensional matching is crucial.

- 16-1: 15mm tube with 6mm rod

- 16-2: 18.5–19mm tube with 8mm rod

- 16-4: 21.5–22mm tube with 10mm rod

- 16-6: 28mm tube with 14mm rod

GASTAC manufactures gas springs matching these specifications within ±0.1mm tolerance, ensuring seamless integration with existing mounting brackets, clevis pins, and installation spaces. Misalignment of even a single millimeter can result in interference, improper operation, or premature wear.

Force ratings are equally important. SUSPA Series 16 covers 60N to 2,000N, and GASTAC offers a full range, with typical increments of 50–100N. Field testing confirms force tolerances within ±2–3%, similar to SUSPA’s manufacturing standards, providing reliable operation in heavy-duty industrial environments and sensitive applications like medical devices. Proper matching of extension and compression forces ensures consistent operation and user safety.

End Fittings and Custom Configurations

SUSPA end fittings—such as A16-B16, AM6-BM6, or A17-B17—dictate the mounting hardware, including ball sockets, clevises, fork heads, or threaded studs. GASTAC offers equivalent fittings with precise dimensional alignment. Critical factors include ball diameter, socket depth, clevis pin spacing, and center-to-center distances.

GASTAC also provides flexible customization options. Customers can order gas springs with non-standard stroke lengths, specific force ratings, or specialized end fittings. This flexibility is particularly valuable when suspa part numbers are discontinued, or when projects require replacement of suspa replacement gas springs with exact mechanical performance, ensuring smooth integration with existing machinery.

Performance, Damping & Reliability of GASTAC Gas Springs

- Temperature Range: Both SUSPA and GASTAC gas springs operate reliably from -30°C to +80°C (-22°F to +176°F), using nitrogen pressurization and oil damping. GASTAC offers stainless steel models for extreme corrosion resistance, comparable to SUSPA’s 316-grade tubes and rods. This ensures long-term reliability in industrial, marine, or outdoor environments.

- Damping & Special Functions: While SUSPA provides specialized variants such as Soft-Stop, TouchLift, or Hydro-Strut, GASTAC produces extension, compression, or combined damping options. For projects requiring precise damping, GASTAC’s engineering team can match performance characteristics of suspa hydraulic lift systems or suspa gas props.

- Noise and Smooth Operation: In furniture, office, or ergonomic applications, suspa struts are prized for their quiet operation. GASTAC gas springs meet or exceed these expectations, delivering smooth extension and compression while minimizing vibration and noise.

GASTAC Gas Springs Quality, Testing & Warranty Assurance

As a reputable GASTAC gas springs struts manufacturer, we ensure high-quality chrome plating, seal materials, tube wall thickness, and gas pressurization. Gas purity and end fitting integrity are closely monitored. Warranty terms are comparable to SUSPA, and failure rates for properly specified and installed units remain below 0.5% over three years.

Technical documentation—including force-stroke curves, CAD models, and material certifications—is provided for regulated industries such as food processing, medical equipment, and laboratories. This allows engineers to confidently replace suspa cylinders, suspa gas props, or other specialized components with GASTAC equivalents.

GASTAC Gas Springs Applications Across Industries

- Industrial Machinery: Stamping presses, safety guards, industrial ovens, and other heavy-duty equipment benefit from robust GASTAC gas springs compatible with suspa gas shocks.

- Automotive & Transportation: Trunk lids, tailgates, and engine hoods rely on consistent performance under thousands of cycles. GASTAC replacements for suspa gas struts australia offer comparable longevity and reliability.

- Medical & Laboratory Equipment: FDA-compliant suspa cylinders or suspa gas props can be replaced with GASTAC models, provided material certifications are verified.

- Furniture & Ergonomic Products: Adjustable chairs, desks, and ergonomic furniture utilize lighter-duty suspa struts or suspa 120N units. GASTAC gas springs provide smooth, quiet operation at competitive prices, ensuring user comfort and satisfaction.

GASTAC to SUSPA Gas Springs Cross-Reference & Installation

- Identify SUSPA part numbers or suspa replacement parts.

- Extract key specifications: tube diameter, rod diameter, stroke, extended and compressed lengths, force rating, and end fitting types.

- Consult GASTAC technical support for equivalent models and specification sheets.

- Verify physical compatibility, including mounting hole spacing, end fitting threads, and overall tolerances.

- Test sample units for force, cycle life, damping, and noise performance before large-scale replacement.

Installation Best Practices: Always mount rod-end up for proper lubrication, use appropriate hardware, and confirm mounting points can handle 2.5× rated force. Manually cycle components to ensure no interference with other mechanisms.

GASTAC Gas Springs Cost, Supply & Advantages

GASTAC gas springs are typically 15–30% less expensive than SUSPA equivalents, with faster turnaround for custom configurations. While SUSPA offers extensive global distribution, GASTAC’s flexible manufacturing is advantageous for projects requiring non-standard suspa replacement gas springs or urgent delivery. For high-volume industrial applications, this cost and time efficiency is especially valuable.

Future Innovations in GASTAC Gas Springs & SUSPA Alternatives

The gas spring industry is evolving with smart gas springs, advanced coatings, and sustainable manufacturing. GASTAC continues innovating in these areas while providing alternatives for suspa lift, suspa gas props, suspa cylinders, and advanced suspa struts systems, meeting Industry 4.0 and environmentally conscious standards. Customers can rely on GASTAC for durable, customizable, and efficient solutions across a wide range of industries.

张航

Stay in the loop