GASTAC Gas Spring Compatible with SPD Gas Springs Specs

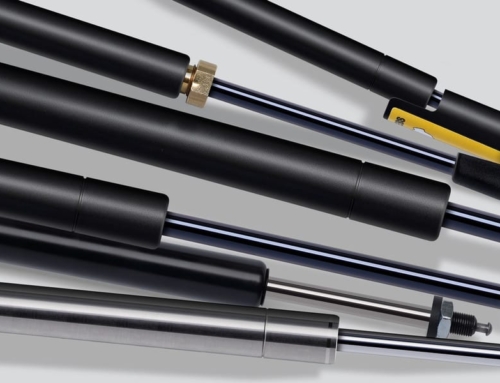

When sourcing replacement gas springs, compatibility is the most critical factor. A replacement must match the original product not only in size, but also in force output, mounting configuration, damping behavior, and long-term reliability. GASTAC gas springs are engineered as direct replacements for SPD gas springs, delivering identical specifications with more cost-efficient sourcing.

With more than two decades of experience in counterbalance and motion-control systems, it is clear that successful replacement depends on strict adherence to original design standards. SPD gas springs, manufactured by ASRaymond (Associated Spring RAYMOND), follow well-established industry specifications. GASTAC carefully matches these specifications, allowing worn or aging SPD units to be replaced seamlessly—without modifying brackets, drilling new holes, or redesigning the application.

This compatibility makes GASTAC a practical alternative for applications ranging from marine hatches and service vehicles to industrial machinery and OEM equipment.

What Are SPD Gas Springs?

SPD gas springs are pre-engineered gas struts—also commonly referred to as spd gas struts or spd gas shocks—designed for controlled lifting, lowering, and counterbalancing. Using compressed nitrogen gas combined with internal hydraulic damping, these components provide smooth, predictable motion while preventing sudden snap-through during operation.

According to ASRaymond technical documentation, SPD gas springs are designed for consistent performance across thousands of cycles. Their standardized dimensions and mounting systems have made them widely adopted in both OEM and aftermarket applications.

Core Technical Specifications of SPD Gas Springs

The engineering behind SPD gas springs is defined by several key technical elements, all of which must be matched for a true replacement:

- Nitrogen Gas Compression: Provides lifting force, typically ranging from 20 to 80 lb (or equivalent Newton ratings)

- Hydraulic Damping Circuit: Controls extension and compression speed, improving safety and user experience

- Surface Protection: Nitride-coated steel for corrosion resistance, with stainless steel options for harsh environments

- Cycle Life: Approximately 30,000 cycles under normal operating conditions

These specifications form the baseline that any compatible replacement—including GASTAC gas springs—must meet or exceed.

GASTAC Gas Spring Compatibility Standards

Matching Critical Dimensions

GASTAC gas springs compatible with SPD gas springs specs are engineered to replicate three essential dimensional parameters:

- Extended Length – total length when fully extended

- Compressed Length – minimum length when compressed, defining stroke

- Force Rating – lifting capacity measured in pounds or Newtons

For example, a GASTAC replacement for the SPD GSNI-5300-20 maintains the same 12–20 inch length range and 20 lb force rating, ensuring identical performance in marine hatch or enclosure applications.

End Fitting and Mounting Compatibility

End fittings are one of the most critical aspects of gas spring replacement. SPD offers several standard configurations, all of which GASTAC matches precisely:

- Type A End Fittings – socket design with safety clip for ball stud mounting

- Type B End Fittings – alternate clip retention systems

- Ball Studs and Brackets – compatible with common 8 mm and 10 mm rod diameters

Proper end fitting compatibility ensures safe installation and prevents premature wear—standards GASTAC rigorously maintains.

SPD Gas Springs Product Range and GASTAC Equivalents

SPD manufactures tens of thousands of standard SKUs. GASTAC provides compatible alternatives for the most commonly specified models:

| SPD GS 5300 60 | SPD GS 5200 30 | SPD GS 5300 40 | SPD GSNI 5000 40 |

|---|---|---|---|

| SPD GS 6687 | SPD GS 5000 20 | SPD GSNI 5000 30 | SPD GS 5100 30 |

| SPD 5200 40 | GSNI 5300 20 | SPD GS 5150 40 | SPD GS 5300 90 |

| SPD GS 5300 80 | SPD GSNI 5150 60 | SPD GS 5200 20 | SPD GS 5300 30 |

| SPD GS 5150 30 | SPD GS 5200 60 | SPD GS 5250 60 | GSNI 2300 80 |

| GSNI 2300 90 | SPD GS 5100 40 | SPD GS 5150 20 | SPD GS 6105 |

| SPD GS 2300 120 | SPD GSNI 4900 20 | SPD GS 8348 | SPD GS 5200 90 |

| SPD GS 6615 | GSNI 2300 120 | GSNI 2300 60 | GSNI 5000 40 |

| GSNI 5150 40 | GSNI 5150 60 | SPD GS 2300 100 | SPD GS 2300 60 |

| SPD GS 5000 60 | SPD GS 5000 80 | SPD GS 5150 90 | SPD GS 5250 45 |

| SPD GS 5250 90 | SPD GS 5300 20 | SPD GS 6119 | SPD GS 6711 |

| SPD GS 6984 | SPD GS 8072 90 | SPD GSNI 2100 90 | SPD GSNI 2300 80 |

| SPD GSNI 2300 90 | SPD GSNI 4900 10 | SPD GSNI 5300 50 | SPD GSNI 6702 |

| SPD GSNI 7183 | SPD GSNI 8652 | SPD GSNI 9090 | GSNI 5300 60 |

| GSNI 5150 40 | GSNI 5300 10 | GSNI 5300 40 | GSNI 2300 100 |

| GSNI 2300 150 | GSNI 5000 20 | GSNI 5000 60 | GSNI 5150 20 |

| GSNI 5200 30 | GSNI 5200 40 | GSNI 5300 30 | GSNI 6687 |

These replacements allow users to substitute spd gas struts with GASTAC alternatives while preserving original functionality.

Specialized Gas Spring Types

Beyond standard compression gas springs, both SPD and GASTAC support specialized variants, including:

- Reducible Force Gas Springs for post-installation adjustment

- Fixed Locking Gas Springs for adjustable workstations

- Welded Blade Designs with integrated mounting brackets

- Stainless Steel Models for marine and corrosive environments

GASTAC maintains compatibility across these categories, ensuring solutions for nearly every spd gas shocks application.

Installation and Replacement Procedures

Replacing SPD gas springs with GASTAC equivalents follows the same safe procedures:

- Support the load before removal

- Disengage safety clips carefully

- Remove the existing gas spring from ball studs

- Align and press the GASTAC replacement into position

- Secure safety clips and test operation

No special tools are required, making replacement straightforward for maintenance teams.

Quality Assurance and Performance Standards

GASTAC gas springs compatible with SPD specifications are manufactured under strict quality controls:

- ISO 9001-certified processes

- High-grade steel tubing and precision seals

- 99.9% purity nitrogen gas

- Batch testing for force accuracy, damping behavior, and seal integrity

Performance tolerances align with industry standards, ensuring consistent operation throughout the rated service life.

Cost Advantages and Long-Term Value

While matching the same specifications as spd gas springs, GASTAC products typically offer a 15–30% cost advantage. This translates into lower total cost of ownership through:

- Reduced unit pricing

- No installation modification costs

- Simplified inventory management

- Reliable long-term supply

For OEMs, distributors, and fleet operators, this balance of compatibility and value is a key advantage.

A Reliable Alternative to SPD Gas Springs

GASTAC gas springs compatible with SPD gas springs specs provide a dependable, specification-matched replacement solution across marine, industrial, and OEM applications. By precisely matching dimensions, force ratings, end fittings, and performance characteristics, GASTAC ensures seamless replacement without compromising safety or functionality.

Whether your application refers to them as spd gas springs, spd gas struts, or spd gas shocks, choosing GASTAC means maintaining original performance while benefiting from more competitive pricing and stable supply.

For successful replacement, accurate specification matching remains essential—and GASTAC delivers that confidence with every compatible gas spring.

张航

Stay in the loop