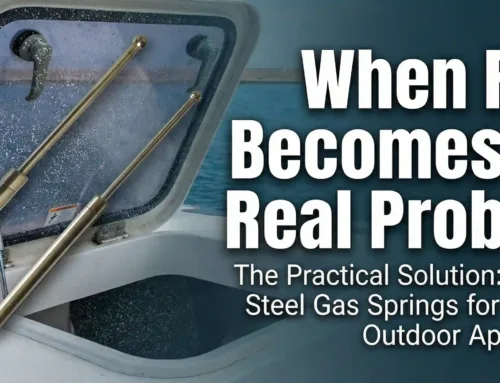

Yes — for most boat owners and marine equipment users, investing in marine gas springs can make daily operation smoother, safer, and far more reliable. We’ll discuss when marine gas struts and marine gas shocks are better suited, how to choose the right specifications, and why partnering with Gastac Gas Springs ensures long-term corrosion resistance and stable performance at sea.

What Are Marine Gas Springs Used For?

Marine gas springs are used in boats and yachts to lift, support, or gently close hatches, lids, and panels. They replace manual effort with gas-assisted motion, making it easy to open heavy parts and preventing sudden slamming. Gastac’s marine-grade units use corrosion-resistant 316L stainless steel, ideal for saltwater environments where durability is essential — following best practices for marine corrosion prevention.

Looking to replace old parts? Visit our product page for reliable, corrosion-proof performance.

When Should You Consider Marine Gas Struts?

If your hatch or compartment door opens frequently — like engine bay covers or deck storage — marine gas struts deliver steady, controlled lifting with no jerky movement. They hold the hatch securely at various angles and protect hinges from vibration damage. With Gastac’s proven quality, these struts stay strong even after years of exposure to spray and sunlight.

How Marine Gas Shocks Improve Longevity

For components near engines or moving decks, marine gas shocks help absorb vibration and reduce metal fatigue. This not only lowers noise levels but also prevents premature wear of hinges and seals. Gastac’s nitrogen-filled shocks are precisely engineered to deliver consistent damping under all marine conditions, from cold mornings to tropical climates.

Typical Marine Applications

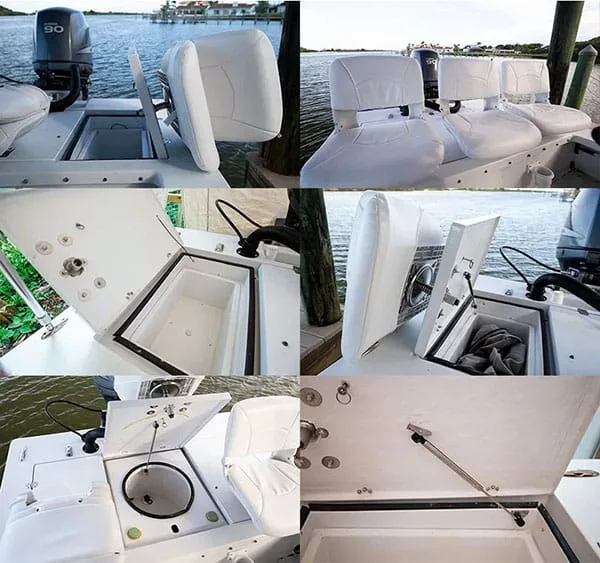

Common applications include:

- 1Hatches and access panels

- 2Deck storage lids

- 3Sail tensioners

- 4Engine bay covers

These are all areas that demand controlled motion and corrosion protection. Gastac Gas Springs has collaborated with numerous boat builders to deliver custom marine gas solutions that meet real-world challenges in these environments.

Key Features and Benefits

- 1Corrosion Resistance: 316L stainless steel resists saltwater exposure.

- 2Smooth Operation: No sudden lid drops, safer for users.

- 3Low Maintenance: Minimal upkeep and long service life.

- 4Stable Quality: Certified under IATF 16949 and ISO 9001:2015.

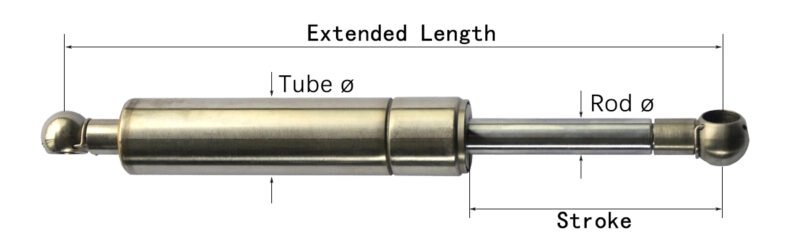

In the quest for marine gas struts? At Gastac, explore a full range of high-quality solutions tailored for marine and boat applications. Our portfolio includes marine gas struts with forces up to 2500 N, featuring M10 threads and matching stainless-steel mounts for easy installation. Every model is carefully selected to meet diverse hatch, lid, and access-panel requirements — ensuring smooth, corrosion-resistant performance in saltwater conditions.

You can browse the full collection in our Product Page to find the gas struts perfectly suited to your specifications.

How to Choosing the Right Product

- Measure your hatch – note the size, weight, and mounting distance.

- Determine lift force – Gastac’s team can assist in force calculations.

- Select material – always choose 316L stainless steel for marine use.

- Verify mounts – ensure stainless brackets for full corrosion protection.

Gastac provides design services for custom applications and assists customers worldwide with selection and installation.

Trusted Marine Partner Since 2007

As a professional gas springs manufacturer and gas springs supplier, Gastac has been supporting the marine sector since 2007. Our products come with a two-year after-sales warranty, stable pricing, and bulk purchasing options for shipyards and distributors.

Conclusion: Are Marine Gas Components Worth It?

If you want smoother hatch operation, longer service life, and reduced maintenance, upgrading to marine-grade gas components is absolutely worth it. Whether it’s marine gas springs for lifting, marine gas struts for control, or marine gas shocks for vibration absorption, Gastac ensures your marine equipment performs with reliability and ease.

- To explore more models and specifications, visit our Product Page

. - If you’re working on a custom design or bulk procurement project, Contact Us

— our engineers can help you choose the right configuration. - And if you simply want to purchase individual marine gas products, visit our Shop

for direct online ordering.

Ian Martin

Stay in the loop