Tension Gas Springs – Reliable Pulling Force for Controlled Motion

Tension Gas Springs – Reliable Pulling Force for Controlled Motion

Compact & Powerful Pull Force

Controlled pulling power in a compact form ensures smooth, precise motion in tight spaces while maintaining reliability during continuous use.

Smooth & Controlled Retraction

Engineered for smooth, consistent retraction while minimizing noise and vibration, ensuring stable, silent operation and enhanced user comfort.

Easy To Install & Maintain, Extends Life

Standard fittings and custom end connectors simplify installation, reduce mechanical wear, and ensure long-lasting, stable performance.

Tension Gas Springs – Reliable Pulling Force for Controlled Motion

Tension Gas Springs – Reliable Pulling Force for Controlled Motion

Compact & Powerful Pull Force

Controlled pulling power in a compact form ensures smooth, precise motion in tight spaces while maintaining reliability during continuous use.

Smooth & Controlled Retraction

Engineered for smooth, consistent retraction while minimizing noise and vibration, ensuring stable, silent operation and enhanced user comfort.

Easy To Install & Maintain, Extends Life

Standard fittings and custom end connectors simplify installation, reduce mechanical wear, and ensure long-lasting, stable performance.

Tension gas springs, also known as pull type gas springs or reverse-acting gas struts, provide controlled pulling force for various applications. Unlike standard compression gas springs that push outward, tension gas springs pull the piston rod inward, making them ideal for lids, hatches, panels, and any mechanism that requires safe and smooth closing.

Constructed with high-quality materials, GASTAC tension gas strut are durable, low-maintenance, and resistant to corrosion. They support adjustable tension and smooth, quiet operation, ensuring consistent performance even under frequent or heavy use. With customizable specifications, they can be adapted to a wide range of mechanical systems and applications.

By combining safety, efficiency, and versatility, pull tension gas struts provide reliable motion control solutions, allowing precise, effortless, and smooth operation in both compact and complex systems.

Tension gas springs, also known as pull type gas springs or reverse-acting gas struts, provide controlled pulling force for various applications. Unlike standard compression gas springs that push outward, tension gas springs pull the piston rod inward, making them ideal for lids, hatches, panels, and any mechanism that requires safe and smooth closing.

Constructed with high-quality materials, GASTAC tension gas strut are durable, low-maintenance, and resistant to corrosion. They support adjustable tension and smooth, quiet operation, ensuring consistent performance even under frequent or heavy use. With customizable specifications, they can be adapted to a wide range of mechanical systems and applications.

By combining safety, efficiency, and versatility, pull tension gas struts provide reliable motion control solutions, allowing precise, effortless, and smooth operation in both compact and complex systems.

Tension Gas Springs Specifications

Tension Gas Springs Specifications

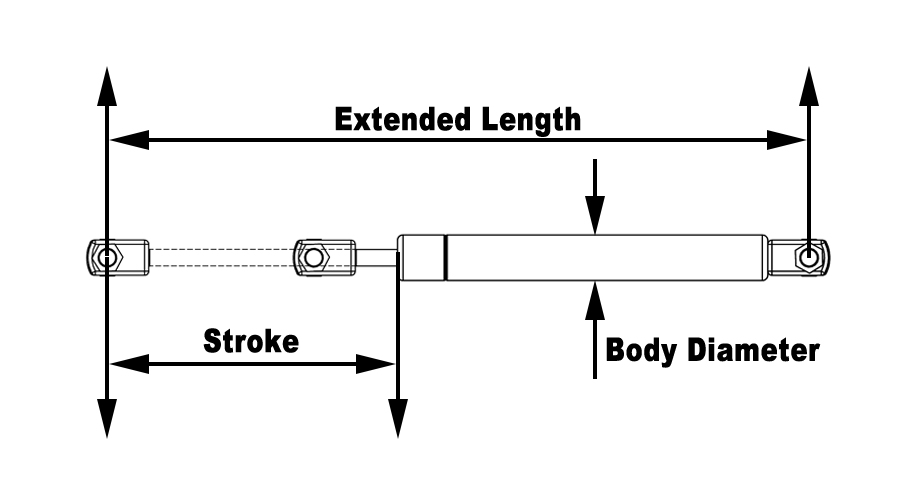

When selecting or replacing a gas spring, it is important to measure the key dimensions accurately. Start with the Rod Diameter and Body Diameter, which determine the strength and load capacity of the gas spring. Next, measure the Stroke, which is the distance the rod can travel between the fully compressed and fully extended positions. Finally, record the Extended Length, which is the total length of the gas spring from the center of one end fitting to the other when fully extended. By following these steps, you can ensure the correct specifications for your application and achieve reliable performance.

When selecting or replacing a gas spring, it is important to measure the key dimensions accurately. Start with the Rod Diameter and Body Diameter, which determine the strength and load capacity of the gas spring. Next, measure the Stroke, which is the distance the rod can travel between the fully compressed and fully extended positions. Finally, record the Extended Length, which is the total length of the gas spring from the center of one end fitting to the other when fully extended. By following these steps, you can ensure the correct specifications for your application and achieve reliable performance.

10-22 Tension Gas Springs

10-22 Tension Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length (mm) | Rod/BodyDiameter (mm) | Force Range F1 (N) | IGS Cross Reference |

| GTL102257156 | 57.15 mm (2.25 in) | 155.96 mm (6.14 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT057154TT |

| GTK102276219 | 76.20 mm (3 in) | 219.46 mm (8.64 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT076218TT |

| GTK102289270 | 88.90 mm (3.50 in) | 270.26 mm (10.64 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT089268TT |

| GTK1022140346 | 139.70 mm (5.50 in) | 346.46 mm (13.64 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT140345TT |

| GTK1022152397 | 152.40 mm (6 in) | 397.26 mm (15.64 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT153396TT |

| GTK1022203473 | 203.20 mm (8 in) | 473.46 mm (18.64 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT203472TT |

| GTK1022254569 | 254.00 mm (10 in) | 568.96 mm (22.40 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT254567TT |

| GTK1022317711 | 317.50 mm (12.50 in) | 711.20 mm (28 in) | M8x1.25 | 10/22 | 25-300 lbs | 1CT318711TT |

14-28 Tension Gas Springs

14-28 Tension Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length (mm) | Rod/BodyDiameter (mm) | Force Range F1 (N) | Ameritool Cross Reference |

| GTL142857207 | 2.25 (57.15) | 8.15 (207.01) | 5.9 (149.86) | 14/28 | 25-350 (111-1557) | 1100-2 |

| GTL1428107308 | 4.25 (107.95) | 12.15 (308.61) | 7.9 (200.66) | 14/28 | 25-350 (111-1557) | 1100-4 |

| GTL1428158410 | 6.25 (158.75) | 16.15 (410.21) | 9.9 (251.46) | 14/28 | 25-350 (111-1557) | 1100-6 |

| GTL1428209511 | 8.25 (209.55) | 20.15 (511.81) | 11.9 (302.26) | 14/28 | 25-350 (111-1557) | 1100-8 |

| GTL1428260613 | 10.25 (260.35) | 24.15 (613.41) | 13.9 (353.06) | 14/28 | 25-350 (111-1557) | 1100-10 |

| GTL1428311715 | 12.25 (311.15) | 28.15 (715.01) | 15.9 (403.86) | 14/28 | 25-350 (111-1557) | 1100-12 |

| GTL1428361816 | 14.25 (361.95) | 32.15 (816.61 | 17.9 (454.66) | 14/28 | 25-350 (111-1557) | 1100-14 |

| GTL1428412918 | 16.25 (412.75) | 36.15 (918.21) | 19.9 (505.46) | 14/28 | 25-350 (111-1557) | 1100-16 |

| GTL14285141121 | 20.25 (514.35) | 44.15 (1121.41) | 23.9 (607.06) | 14/28 | 25-350 (111-1557) | 1100-20 |

| GTL14286151324 | 24.25 (615.95) | 52.15 (1324.61) | 27.9 (708.66) | 14/28 | 25-350 (111-1557) | 1100-24 |

Custom Tension Gas Springs to Fit Your Application

GASTAC offers custom tension gas springs and pull-type gas struts with selectable materials, dimensions, and force—custom specs available on request.

Custom Tension Gas Springs to Fit Your Application

GASTAC offers custom tension gas springs and pull-type gas struts with selectable materials, dimensions, and force—custom specs available on request.