Stainless Steel Gas Struts — Durable Marine & Industrial Solutions

Stainless Steel Gas Struts — Durable Marine & Industrial Solutions

Excellent corrosion resistance

High-quality stainless gas struts deliver strong corrosion resistance and 100,000+ piston cycles.

Wide range of applications

Suitable for all industries, from medical and marine to industrial equipment, handling diverse scenarios with ease

Choose for easy installation

Simply select the correct size and pressure, and enjoy quick, hassle-free installation for any application.

Stainless Steel Gas Struts — Durable Marine & Industrial Solutions

Stainless Steel Gas Struts — Durable Marine & Industrial Solutions

Excellent corrosion resistance

High-quality stainless gas struts deliver strong corrosion resistance and 100,000+ piston cycles.

Wide range of applications

Suitable for all industries, from medical and marine to industrial equipment, handling diverse scenarios with ease

Choose for easy installation

Simply select the correct size and pressure, and enjoy quick, hassle-free installation for any application.

GASTAC stainless gas struts are built for strength, durability, and corrosion resistance. Offered in 304 and 316L stainless steel, they meet different environmental demands: 304 suits outdoor equipment, medical devices, and industrial machinery, while 316L, with superior resistance to saltwater and chemicals, is perfect for marine, coastal, and food-grade applications.

Each strut is rigorously tested to ensure long service life, smooth motion, and consistent performance. With customizable sizes and pressures, GASTAC delivers reliable lifting, positioning, and support across sectors from boats and hospitals to food processing plants and heavy-duty machinery.

We stock a wide range of the most requested stainless steel gas springs marine, and any other sizes can be made to order.

GASTAC stainless gas struts are built for strength, durability, and corrosion resistance. Offered in 304 and 316L stainless steel, they meet different environmental demands: 304 suits outdoor equipment, medical devices, and industrial machinery, while 316L, with superior resistance to saltwater and chemicals, is perfect for marine, coastal, and food-grade applications.

Each strut is rigorously tested to ensure long service life, smooth motion, and consistent performance. With customizable sizes and pressures, GASTAC delivers reliable lifting, positioning, and support across sectors from boats and hospitals to food processing plants and heavy-duty machinery.

We stock a wide range of the most requested stainless steel gas springs marine, and any other sizes can be made to order.

Stainless Steel Gas Strut Types

Stainless Steel Gas Strut Types

316L Stainless Steel Gas Struts

316L stainless gas struts are engineered for maximum corrosion resistance, making them the top choice for marine, coastal, chemical, and medical environments. With enhanced durability against saltwater, chemicals, and harsh conditions, they deliver extended service life and reliable performance even in the toughest applications. For industries where safety and longevity are critical, 316L offers unmatched quality.

316L Stainless Steel Gas Struts

316L stainless gas struts are engineered for maximum corrosion resistance, making them the top choice for marine, coastal, chemical, and medical environments. With enhanced durability against saltwater, chemicals, and harsh conditions, they deliver extended service life and reliable performance even in the toughest applications. For industries where safety and longevity are critical, 316L offers unmatched quality.

304 Stainless Steel Gas Struts

304 stainless gas struts provide an excellent balance of performance and cost-effectiveness. With strong resistance to everyday rust and oxidation, they are widely used in outdoor equipment, industrial machinery, and food-grade applications. Their durability and hygienic properties make them ideal for environments that require cleanliness and reliability, while offering an economical choice for most standard projects.

304 Stainless Steel Gas Struts

304 stainless gas struts provide an excellent balance of performance and cost-effectiveness. With strong resistance to everyday rust and oxidation, they are widely used in outdoor equipment, industrial machinery, and food-grade applications. Their durability and hygienic properties make them ideal for environments that require cleanliness and reliability, while offering an economical choice for most standard projects.

Stainless Steel Gas Strut Specifications

Stainless Steel Gas Strut Specifications

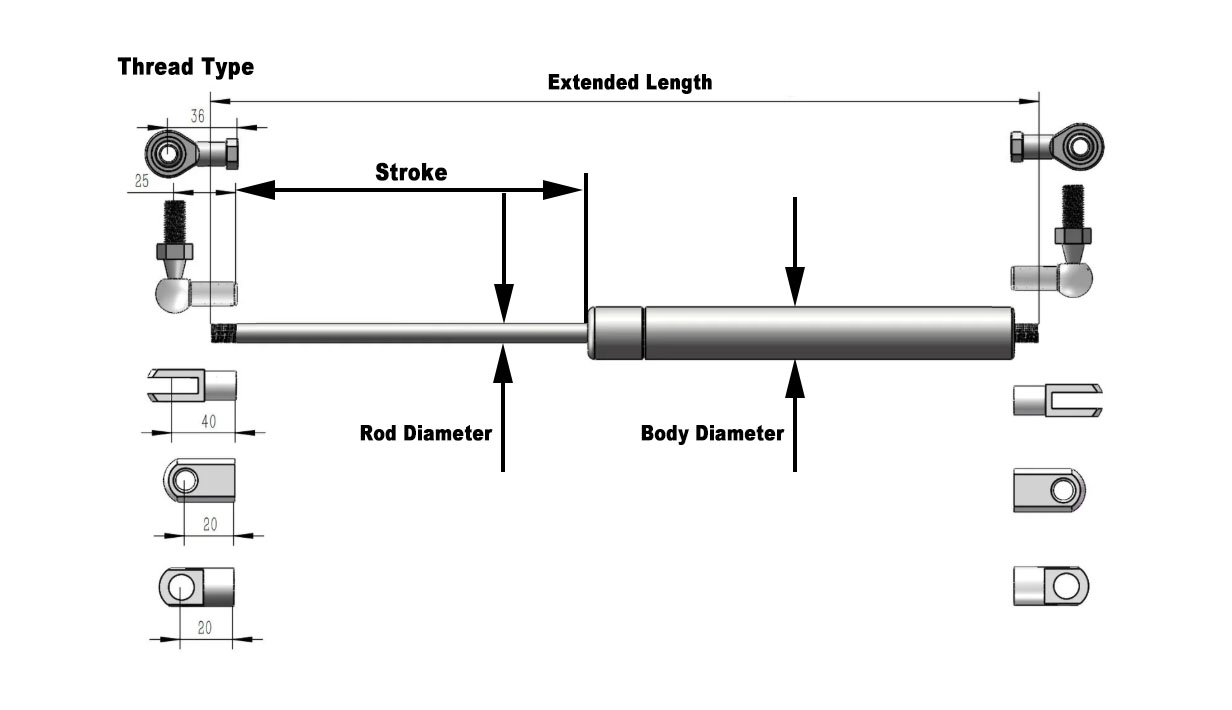

When selecting or replacing a gas spring, it is important to measure the key dimensions accurately. Start with the Rod Diameter and Body Diameter, which determine the strength and load capacity of the gas spring. Next, measure the Stroke, which is the distance the rod can travel between the fully compressed and fully extended positions. Finally, record the Extended Length, which is the total length of the gas spring from the center of one end fitting to the other when fully extended. By following these steps, you can ensure the correct specifications for your application and achieve reliable performance.

When selecting or replacing a gas spring, it is important to measure the key dimensions accurately. Start with the Rod Diameter and Body Diameter, which determine the strength and load capacity of the gas spring. Next, measure the Stroke, which is the distance the rod can travel between the fully compressed and fully extended positions. Finally, record the Extended Length, which is the total length of the gas spring from the center of one end fitting to the other when fully extended. By following these steps, you can ensure the correct specifications for your application and achieve reliable performance.

6-15 Stainless Steel Gas Springs

6-15 Stainless Steel Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Lift Easy Cross Reference |

| GTS61515550 | 40 | 155 | 115 | 6/15 | 50-400 | GSSK15-155/050N |

| GTS61519550 | 60 | 225 | 165 | 6/15 | 50-400 | GSSK15-195/050N |

| GTS61523550 | 80 | 235 | 155 | 6/15 | 50-400 | GSSK15-235/050N |

| GTS61525550 | 80 | 255 | 175 | 6/15 | 50-400 | GSSK15-255/050N |

| GTS61527550 | 100 | 275 | 175 | 6/15 | 50-400 | GSSK15-275/050N |

| GTS61531550 | 120 | 315 | 195 | 6/15 | 50-400 | GSSK15-315/050N |

| GTS61533050 | 125 | 330 | 205 | 6/15 | 50-400 | GSSK15-330/050N |

| GTS61537550 | 150 | 375 | 225 | 6/15 | 50-400 | GSSK15-375/050N |

| GTS61539050 | 160 | 390 | 230 | 6/15 | 50-400 | GSSK15-390/050N |

| GTS61543050 | 175 | 430 | 255 | 6/15 | 50-400 | GSSK15-430/050N |

| GTS61550550 | 210 | 505 | 295 | 6/15 | 50-400 | GSSK15-505/050N |

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Lift Easy Cross Reference |

| GTS61515550 | 40 | 155 | 115 | 6/15 | 50-400 | GSSK15-155/050N |

| GTS61519550 | 60 | 225 | 165 | 6/15 | 50-400 | GSSK15-195/050N |

| GTS61523550 | 80 | 235 | 155 | 6/15 | 50-400 | GSSK15-235/050N |

| GTS61525550 | 80 | 255 | 175 | 6/15 | 50-400 | GSSK15-255/050N |

| GTS61527550 | 100 | 275 | 175 | 6/15 | 50-400 | GSSK15-275/050N |

| GTS61531550 | 120 | 315 | 195 | 6/15 | 50-400 | GSSK15-315/050N |

| GTS61533050 | 125 | 330 | 205 | 6/15 | 50-400 | GSSK15-330/050N |

| GTS61537550 | 150 | 375 | 225 | 6/15 | 50-400 | GSSK15-375/050N |

| GTS61539050 | 160 | 390 | 230 | 6/15 | 50-400 | GSSK15-390/050N |

| GTS61543050 | 175 | 430 | 255 | 6/15 | 50-400 | GSSK15-430/050N |

| GTS61550550 | 210 | 505 | 295 | 6/15 | 50-400 | GSSK15-505/050N |

8-18 Stainless Steel Gas Springs

8-18 Stainless Steel Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | IGS Cross Reference |

| GTS818310700 | 120 | 310 | 190 | 8/18 | 100-700 | GSSK18-310/100N |

| GTS818390700 | 160 | 390 | 230 | 8/18 | 100-700 | GSSK18-390/100N |

| GTS818410700 | 170 | 410 | 240 | 8/18 | 100-700 | GSSK18-410/100N |

| GTS818510700 | 215 | 510 | 295 | 8/18 | 100-700 | GSSK18-510/100N |

| GTS818525700 | 225 | 525 | 300 | 8/18 | 100-700 | GSSK18-525/100N |

| GTS818585700 | 255 | 585 | 330 | 8/18 | 100-700 | GSSK18-585100N |

| GTS818610700 | 265 | 610 | 345 | 8/18 | 100-700 | GSSK18-610/100N |

| GTS818630700 | 280 | 630 | 350 | 8/18 | 100-700 | GSSK18-630/100N |

| GTS818710700 | 315 | 710 | 395 | 8/18 | 100-700 | GSSK18-710/100N |

10-22 Stainless Steel Gas Springs

10-22 Stainless Steel Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Lift Easy Cross Reference |

| GTS10225851100 | 255 | 585 | 330 | 10/22 | 100-1100 | GSSK22-585/100N |

| GTS10227001100 | 305 | 700 | 395 | 10/22 | 100-1100 | GSSK22-700/100N |

| GTS10227101100 | 305 | 710 | 405 | 10/22 | 100-1100 | GSSK22-710/100N |

| GTS10228201100 | 360 | 820 | 460 | 10/22 | 100-1000 | GSSK22-820/100N |

14-28 Stainless Steel Gas Springs

14-28 Stainless Steel Gas Springs

| GASTAC Code | Stroke Length (mm) | Extended Length (mm) | Compressed Length C (mm) | Rod/Body Diameter (mm) | Force Range F1 (N) | Lift Easy Cross Reference |

| GTS142811002000 | 500 | 1100 | 600 | 14/28 | 100-2000 | GSSK28-1100/100N |

| GTS142812002000 | 545 | 1200 | 655 | 14/28 | 100-2000 | GSSK28-1200/100N |

Stainless Steel Gas Springs

Stainless Steel Gas Springs

| Gastac Product Code | Expanded Length: | Compressed Length | Stroke | Force (lbs) |

Attwood Product Code |

| GTS25420 | 10″ | 7″ | 3″ | 20 | ST30205 |

| GTS25440 | 10″ | 7″ | 3″ | 40 | ST30405 |

| GTS19020 | 7.5″ | 5.25″ | 2.25″ | 20 | ST31205 |

| GTS26630 | 10.5″ | 7.5″ | 3″ | 30 | ST32305 |

| GTS38120 | 15″ | 9.5″ | 5.5″ | 20 | ST33205 |

| GTS38140 | 15″ | 9.5″ | 5.5″ | 40 | ST33405 |

| GTS38160 | 15″ | 9.5″ | 5.5″ | 60 | ST33605 |

| GTS508120 | 20″ | 12″ | 8″ | 120 | ST341205 |

| GTS50820 | 20″ | 12″ | 8″ | 20 | ST34205 |

| GTS50830 | 20″ | 12″ | 8″ | 30 | ST34305 |

| GTS50840 | 20″ | 12″ | 8″ | 40 | ST34405 |

| GTS50880 | 20″ | 12″ | 8″ | 80 | ST34805 |

| GTS50890 | 20″ | 12″ | 8″ | 90 | ST34905 |

| GTS30540 | 12.04″ | 8.46″ | 3.58″ | 40 | ST35405 |

| GTS30550 | 12.04″ | 8.46″ | 3.58″ | 50 | ST35505 |

| GTS43640 | 17.2″ | 10.2″ | 7″ | 40 | ST36405 |

| GTS43670 | 17.2″ | 10.2″ | 7″ | 70 | ST36705 |

| GTS43690 | 17.2″ | 10.2″ | 7″ | 90 | ST36905 |

Stainless Steel Gas Springs

Stainless Steel Gas Springs

| Gastac Product Code | Expanded Length: | Compressed Length | Stroke | Force (lbs) |

Boat Outfitters Product Code |

| GTS508100 | 20″ | 12″ | 8″ | 20-100 | 260-2486 |

| GTS30560 | 12″ | 8″ | 4″ | 20-60 | 060-3547-CP |

| GTS43660 | 17.20″ | 10.20″ | 7″ | 20-60 | 260-1679-CP |

| GTS19030 | 7.5″ | 5.5″ | 2″ | 5-30 | 060-3586-CP |

| GTS58460 | 23″ | 13″ | 10″ | 90 | 060-3633 |

| GTS47060 | 18.5″ | 11.25″ | 7.25″ | 20-60 | 060-3570-CP |

| GTS66620 | 26.25″ | 14.7″ | 11.55″ | 20 | 060-3698 |

Stainless Steel Gas Strut Applications

Marine Industry

GASTAC marine gas springs and boat gas struts resist corrosion from saltwater and harsh weather, ensuring reliable support for hatches, doors, and lids on boats and yachts.

Food Safety

In food processing, GASTAC Stainless Gas Springs are hygienic, rust-resistant, and easy to clean, providing smooth motion control that meets strict sanitation and safety requirements.

Medical Equipment

GASTAC Stainless Gas Springs provide precise and stable force for hospital beds, diagnostic tools, and lab devices, ensuring durability, safety, and easy sterilization in medical use.

Stainless Steel Gas Strut Applications

Gas Spring End Fittings

Gas Spring End Fittings

Gas strut Ball Ends

Gas strut Ball Ends

Gas strut ball ends, also called ball joints or ball sockets, are essential fittings that connect gas springs securely to mounting points. They allow smooth pivoting movement, reduce wear, and improve load transfer. Available in steel, stainless, or plastic, ball ends ensure durability, easy installation, and reliable performance in varied applications.

Eye End Fittings

Eye End Fittings

Eye end fittings are precision-engineered connectors that attach gas springs to brackets or mounting points, providing a secure and stable connection. They allow controlled pivoting motion, reduce wear, extend the lifespan of the gas strut, and enhance operational safety. Eye end fittings are suitable for automotive, marine, industrial, and furniture applications.

Female Rod Ends

Female Rod Ends

Female rod ends provide a precise connection point between the gas strut and mounting hardware. Designed for controlled pivoting, they ensure smooth movement, reliable load transfer, and stable alignment. These connectors make installation straightforward while maintaining consistent performance and safety.

Gas strut Ball Ends

Gas strut Ball Ends

Gas strut ball ends, also called ball joints or ball sockets, are essential fittings that connect gas springs securely to mounting points. They allow smooth pivoting movement, reduce wear, and improve load transfer. Available in steel, stainless, or plastic, ball ends ensure durability, easy installation, and reliable performance in varied applications.

Eye End Fittings

Eye End Fittings

Eye end fittings are precision-engineered connectors that attach gas springs to brackets or mounting points, providing a secure and stable connection. They allow controlled pivoting motion, reduce wear, extend the lifespan of the gas strut, and enhance operational safety. Eye end fittings are suitable for automotive, marine, industrial, and furniture applications.

Female Rod Ends

Female Rod Ends

Female rod ends provide a precise connection point between the gas strut and mounting hardware. Designed for controlled pivoting, they ensure smooth movement, reliable load transfer, and stable alignment. These connectors make installation straightforward while maintaining consistent performance and safety.