Stainless Steel Gas Struts Quality Value

In demanding environments, standard gas struts simply won’t suffice. That’s where suportes de gás em aço inoxidável shine, offering unparalleled resistance to corrosion, extreme temperatures, and harsh chemicals. Stainless gas shocks importance spans numerous industries, from marine and food processing to medical and pharmaceutical sectors. Why? Because reliability and longevity are paramount. That’s why GASTAC stands as a leading manufacturer of high-quality stainless gas springs, designed to withstand the harshest conditions. We understand the critical importance of durable, precise motion control, and our commitment to excellence shines through in every product.

GASTAC, a prominent Chinese producer of marine gas struts manufacturer, leverages cutting-edge manufacturing and expert personnel. For tailored stainless steel gas springs, email [sales@gastac.com]. For standardized stainless steel gas strut dimensions, explore the GASTAC loja on-line for simple ordering and dependable products.

What is Stainless Steel Gas Struts?

Stainless steel gas struts are motion control devices using compressed gas within a cylinder.Made from corrosion-resistant stainless steel, they offer durable support and controlled movement in demanding environments like marine, food, and medical applications

How Stainless Steel Gas Strut Works?

A stainless steel gas strut uses compressed nitrogen gas inside a cylinder. As the rod extends or compresses, the gas pressure controls the movement. Seals prevent gas leakage. The stainless steel construction ensures corrosion resistance. They provide smooth, controlled motion and support in various applications.

Why Choose Stainless Steel Over Other Materials?

Stainless gas strut offers superior corrosion resistance, durability, and hygiene compared to other materials. It withstands harsh environments, extreme temperatures, and is easy to clean, making it ideal for demanding applications.

Stainless Steel Gas Struts Material Grades (304 vs 316)

304 and 316 suportes de gás em aço inoxidável offer distinct advantages. 304 is cost-effective, resisting most corrosion. 316, containing molybdenum, provides superior corrosion resistance, especially in chloride-rich (marine) environments. Choose based on specific application demands.

Stainless Steel Gas Struts Material Grades (304 vs 316)

- Corrosion Resistance: Stainless steel gas strut resists rust and chemical damage, crucial in harsh environments.

- Durability & Longevity: Robust material ensures long-term performance and withstands heavy loads.

- Hygiene & Cleanliness: Non-porous surface prevents bacteria growth, ideal for sensitive applications.

- Temperature Tolerance: Maintains structural integrity across wide temperature ranges.

Stainless Steel Gas Struts Applications

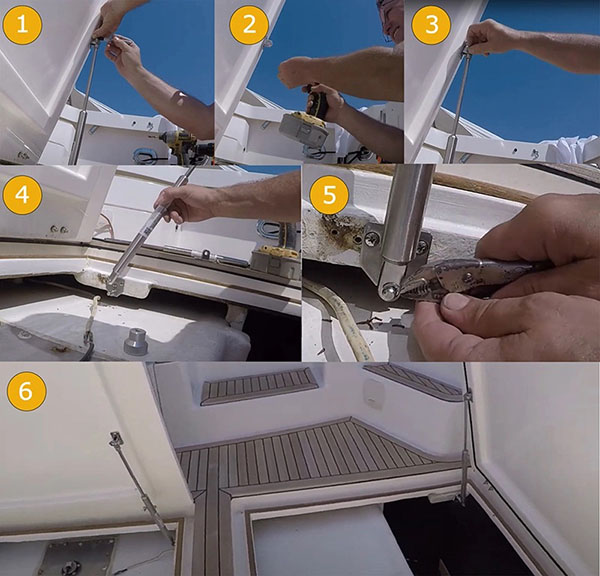

Marine (Boat Hatches, Lids)

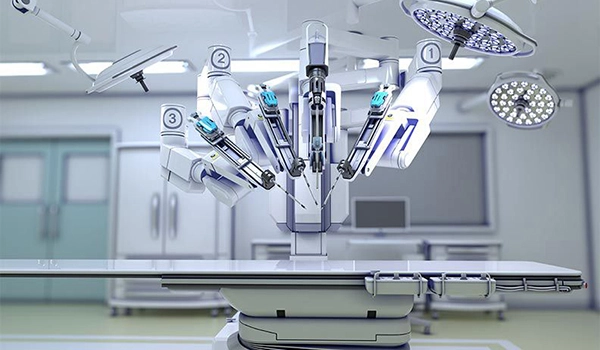

Medical Equipment

Food Processing

Industrial Machinery

Customization and Specifications

Custom stainless steel gas struts tailor force,stroke, extended length, end fittings, and materials to specific needs. This ensures optimal performance and fit for unique applications, enhancing durability and functionality.

Stainless Steel Gas Struts End fitting

Custom stainless steel gas struts tailor force,stroke, extended length, end fittings, and materials to specific needs. This ensures optimal performance and fit for unique applications, enhancing durability and functionality.

How to determine the right specifications?

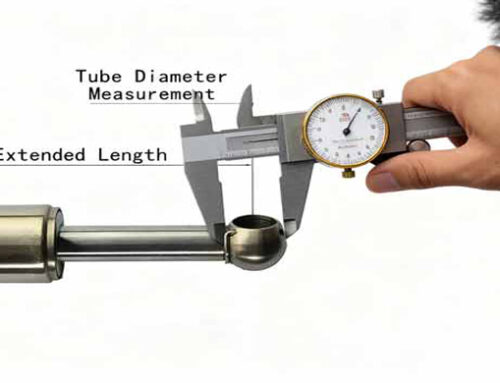

To obtain the dimensions of the stainless steel gas spring by measuring the stroke, extended length, rod Ø, tube Ø as shown in the illustration, to select the appropriate end fitting and to calculate the force by determining the gravitational force of the object to be lifted.

If you are having trouble with this operation or don’t understand it, you can email GASTAC at sales@gastac.com and we will help you to build stainless steel sas struts at a good price. Or you can also jump to our Gas Spring Shop to choose the right stainless steel gas spring for you!

Stainless Steel Gas Struts installation techniques

- Precise measurement & marking.

- Correct hardware selection.

- Proper alignment (no side loading).

- Secure end fitting attachment.

- Smooth operation verification.

- Full stroke length allowance.

- Manufacturer’s instructions followed.

Maintenance tips for extending lifespan

Extending the life of suportes de gás em aço inoxidável involves proper installation, maintenance, and environmental considerations. Here’s a concise guide:

- Install Correctly: Align properly, secure mounts, avoid overextension.

- Maintain Regularly: Inspect for damage, clean, check seals, lubricate (if needed).

- Protect Environmentally: Avoid extreme temps, chemicals, saltwater; shield from damage.

- Store Properly: Clean, dry, extended position if possible.

- Choose Quality: Buy from reputable manufacturers, select correct material.

张航

Fique por dentro das informações

Assine nosso boletim informativo gratuito.

Fique por dentro das informações