Precision Engineered Car OEM Gas Springs – Trusted by Automotive Manufacturers

Precision Engineered Car OEM Gas Springs – Trusted by Automotive Manufacturers

Perfect Fit & Finish

Constructed with high-quality, robust materials, GASTAC car OEM gas springs ensure long-lasting and reliable performance, even under frequent use.

Easy Installation

Designed for straightforward installation, these springs are compatible with a wide range of setups, saving time and effort during assembly.

Adjustable Operation

GASTAC car OEM gas springs must integrate flawlessly—no squeaks, rattles, or awkward resistance—maintaining the premium feel of the vehicle.

Precision Engineered Car OEM Gas Springs – Trusted by Automotive Manufacturers

Precision Engineered Car OEM Gas Springs – Trusted by Automotive Manufacturers

Perfect Fit & Finish

Constructed with high-quality, robust materials, GASTAC car OEM gas springs ensure long-lasting and reliable performance, even under frequent use.

Easy Installation

Designed for straightforward installation, these springs are compatible with a wide range of setups, saving time and effort during assembly.

Adjustable Operation

GASTAC car OEM gas springs must integrate flawlessly—no squeaks, rattles, or awkward resistance—maintaining the premium feel of the vehicle.

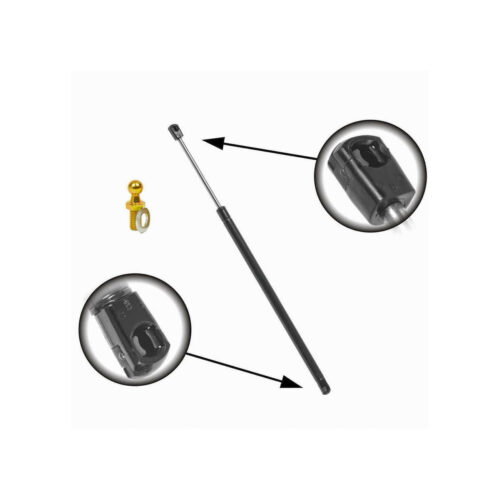

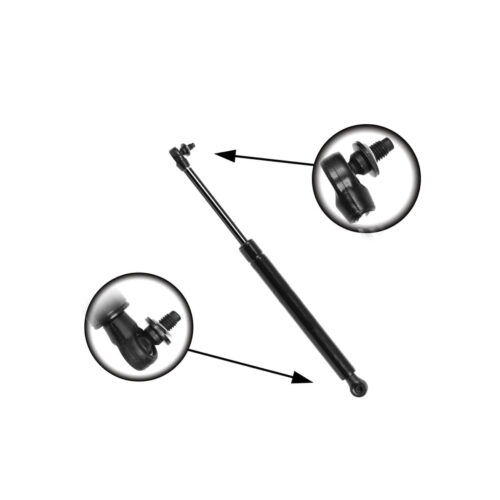

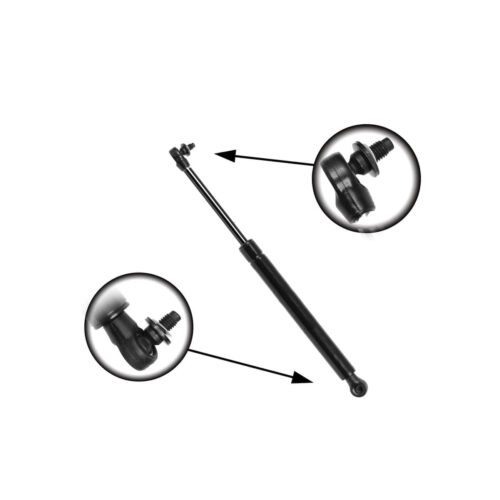

GASTAC Car OEM gas springs are designed to meet the highest automotive standards, providing smooth, stable, and reliable motion for hoods, trunks, doors, and seats. Manufactured under IATF16949 certification, each gas strut undergoes strict quality control, ensuring long-lasting performance, corrosion resistance, and durability even under extreme temperature and vibration conditions.

With over 20 years of industry expertise, GASTAC delivers complete OEM customization services — including design development, force adjustment, material selection, and personalized logo marking. Every gas spring is tested for over 100,000 cycles to guarantee precise operation and safety, making GASTAC a trusted partner for global automotive manufacturers seeking high-performance gas spring solutions.

GASTAC Car OEM gas springs are designed to meet the highest automotive standards, providing smooth, stable, and reliable motion for hoods, trunks, doors, and seats. Manufactured under IATF16949 certification, each gas strut undergoes strict quality control, ensuring long-lasting performance, corrosion resistance, and durability even under extreme temperature and vibration conditions.

With over 20 years of industry expertise, GASTAC delivers complete OEM customization services — including design development, force adjustment, material selection, and personalized logo marking. Every gas spring is tested for over 100,000 cycles to guarantee precise operation and safety, making GASTAC a trusted partner for global automotive manufacturers seeking high-performance gas spring solutions.

Automotive Brands Compatible with GASTAC

Automotive Brands Compatible with GASTAC

AUDI

BMW

MERCEDES

PORSCHE

VOLKSWAGEN

HYUNDAI

KIA

CHEYSLER

DODGE

JEEP

FORD

GM

RANG ROVER

VOLVO

HONDA

MAZDA

NISSAN

MITSUBISHI

SUBARU

SUZUKI

TOYOTA

Car OEM Gas Spring

Car OEM Gas Spring

Car OEM Gas Spring Applications

GASTAC car OEM gas springs are used across multiple vehicle areas to deliver reliable lifting, holding, and damping functions. In the hood, they assist with easy engine access; in the trunk or tailgate, they enable smooth opening and controlled closing. Installed in doors, they enhance safety and comfort, while in seats they allow adjustable backrest positioning. For convertible roofs, GASTAC gas struts ensure stable and balanced movement, providing consistent performance and durability in every automotive environment.

Car OEM Gas Spring Applications

GASTAC car OEM gas springs are used across multiple vehicle areas to deliver reliable lifting, holding, and damping functions. In the hood, they assist with easy engine access; in the trunk or tailgate, they enable smooth opening and controlled closing. Installed in doors, they enhance safety and comfort, while in seats they allow adjustable backrest positioning. For convertible roofs, GASTAC gas struts ensure stable and balanced movement, providing consistent performance and durability in every automotive environment.

Hood struts support the vehicle hood, allowing it to lift effortlessly and stay open securely during maintenance or inspection. They replace traditional metal rods, improving safety and convenience. With gas-assisted operation, they provide smooth, controlled motion, prevent sudden slamming, and reduce manual effort, ensuring long-lasting performance and reliability for every vehicle.

Boot struts are gas springs designed to lift and hold the car boot or trunk open smoothly and safely. They provide controlled motion, preventing sudden drops and ensuring easy access when loading or unloading. Built for durability and corrosion resistance, boot struts enhance user comfort, safety, and convenience in daily vehicle operation.

Tailgate struts are gas springs that assist in lifting and holding a vehicle’s tailgate securely. They provide smooth, controlled motion, preventing sudden slamming and reducing physical effort. Built for durability and corrosion resistance, tailgate struts enhance safety, convenience, and ease of access, ensuring reliable performance for daily use.

Trunk struts are gas springs that assist in lifting and securely holding a vehicle’s trunk open. They provide smooth, controlled motion, preventing sudden slamming and reducing manual effort. Durable and corrosion-resistant, trunk struts enhance safety, convenience, and ease of access, making loading and unloading effortless in everyday use.

Bonnet struts are gas springs that support the car bonnet, enabling effortless lifting and secure holding during maintenance. They ensure smooth, controlled motion, prevent sudden closures, and reduce manual effort. Designed for durability and corrosion resistance, bonnet struts improve safety, convenience, and reliability for everyday vehicle use.

Hood struts support the vehicle hood, allowing it to lift effortlessly and stay open securely during maintenance or inspection. They replace traditional metal rods, improving safety and convenience. With gas-assisted operation, they provide smooth, controlled motion, prevent sudden slamming, and reduce manual effort, ensuring long-lasting performance and reliability for every vehicle.

Boot struts are gas springs designed to lift and hold the car boot or trunk open smoothly and safely. They provide controlled motion, preventing sudden drops and ensuring easy access when loading or unloading. Built for durability and corrosion resistance, boot struts enhance user comfort, safety, and convenience in daily vehicle operation.

Tailgate struts are gas springs that assist in lifting and holding a vehicle’s tailgate securely. They provide smooth, controlled motion, preventing sudden slamming and reducing physical effort. Built for durability and corrosion resistance, tailgate struts enhance safety, convenience, and ease of access, ensuring reliable performance for daily use.

Trunk struts are gas springs that assist in lifting and securely holding a vehicle’s trunk open. They provide smooth, controlled motion, preventing sudden slamming and reducing manual effort. Durable and corrosion-resistant, trunk struts enhance safety, convenience, and ease of access, making loading and unloading effortless in everyday use.

Bonnet struts are gas springs that support the car bonnet, enabling effortless lifting and secure holding during maintenance. They ensure smooth, controlled motion, prevent sudden closures, and reduce manual effort. Designed for durability and corrosion resistance, bonnet struts improve safety, convenience, and reliability for everyday vehicle use.