GASTAC Gas Springs – Precision Motion, Reliable Support

GASTAC Gas Springs – Precision Motion, Reliable Support

High-performance gas springs for automotive, industrial, and furniture applications. Smooth, safe, and built to last.

High-performance gas springs for automotive, industrial, and furniture applications. Smooth, safe, and built to last.

GASTAC Gas Springs – Precision Motion, Reliable Support

GASTAC Gas Springs – Precision Motion, Reliable Support

High-performance gas springs for automotive, industrial, and furniture applications. Smooth, safe, and built to last.

High-performance gas springs for automotive, industrial, and furniture applications. Smooth, safe, and built to last.

Gas springs, auch bekannt als gas struts oder gas lift supports, provide controlled lifting, lowering, and positioning in countless applications—from car hoods and tailgates to furniture, machinery, and medical equipment.

GASTAC manufactures a complete range of gas springs with precise force, lange Nutzungsdauer, und stable performance for global OEM und aftermarket clients.

Gas springs, auch bekannt als gas struts oder gas lift supports, provide controlled lifting, lowering, and positioning in countless applications—from car hoods and tailgates to furniture, machinery, and medical equipment.

GASTAC manufactures a complete range of gas springs with precise force, lange Nutzungsdauer, und stable performance for global OEM und aftermarket clients.

Gas Springs Category

Gas Springs Category

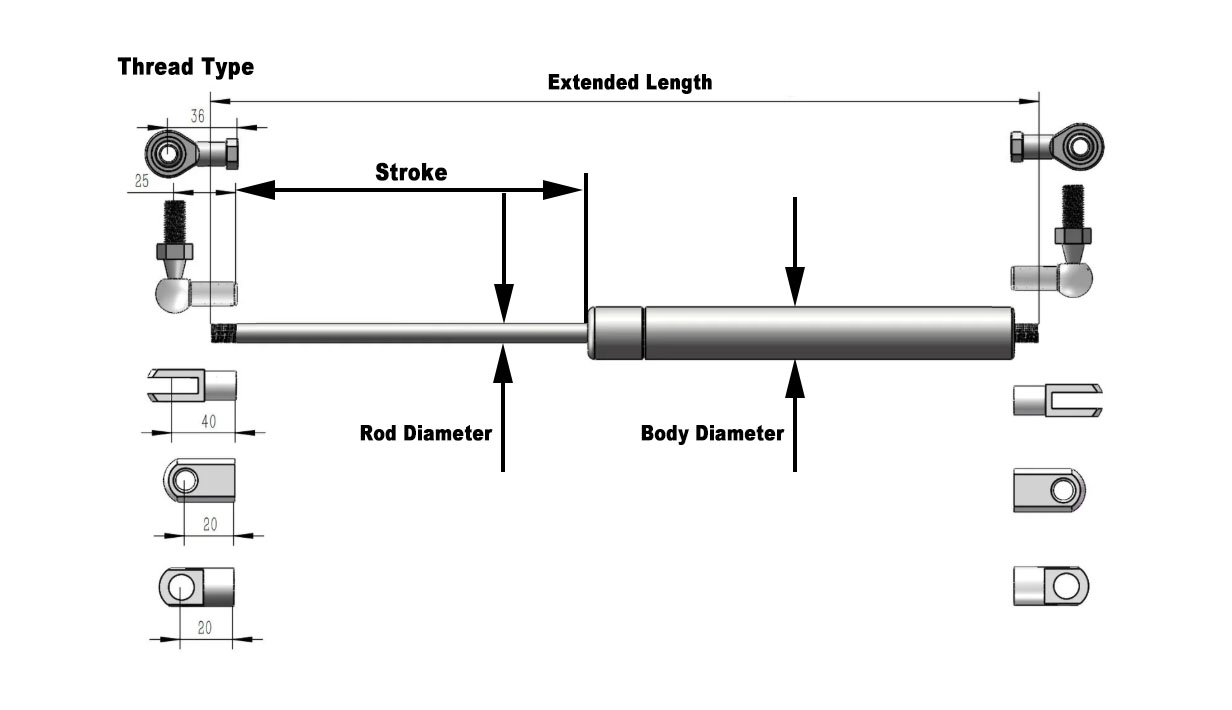

Gas Springs Specifications

Bei der Auswahl oder dem Austausch einer Gasfeder ist es wichtig, die wichtigsten Maße genau zu messen. Beginnen Sie mit der Stabdurchmesser und Durchmesser des Körpers, die die Festigkeit und Belastbarkeit der Gasfeder bestimmen. Messen Sie als nächstes die Schlaganfall, Dies ist die Strecke, die die Stange zwischen der vollständig eingefahrenen und der vollständig ausgefahrenen Position zurücklegen kann. Notieren Sie schließlich die Erweiterte Länge, Dies ist die Gesamtlänge der Gasfeder von der Mitte des einen Endstücks bis zum anderen, wenn sie vollständig ausgefahren ist. Wenn Sie diese Schritte befolgen, können Sie die richtigen Spezifikationen für Ihre Anwendung sicherstellen und eine zuverlässige Leistung erzielen.

Gas Springs Specifications

Bei der Auswahl oder dem Austausch einer Gasfeder ist es wichtig, die wichtigsten Maße genau zu messen. Beginnen Sie mit der Stabdurchmesser und Durchmesser des Körpers, die die Festigkeit und Belastbarkeit der Gasfeder bestimmen. Messen Sie als nächstes die Schlaganfall, Dies ist die Strecke, die die Stange zwischen der vollständig eingefahrenen und der vollständig ausgefahrenen Position zurücklegen kann. Notieren Sie schließlich die Erweiterte Länge, Dies ist die Gesamtlänge der Gasfeder von der Mitte des einen Endstücks bis zum anderen, wenn sie vollständig ausgefahren ist. Wenn Sie diese Schritte befolgen, können Sie die richtigen Spezifikationen für Ihre Anwendung sicherstellen und eine zuverlässige Leistung erzielen.